OCR Specification focus:

‘Apply procedures for electrical methods to find c of a metal block and a liquid accurately.’

Understanding experimental techniques for measuring the specific heat capacity of materials is essential in thermal physics. This topic focuses on accurate methods using electrical heating for both metal blocks and liquids.

Measuring Specific Heat Capacity (c)

The specific heat capacity (c) of a substance quantifies how much energy is required to raise the temperature of 1 kg of the substance by 1 K (or 1 °C). Accurate determination depends on controlling energy transfer, minimising heat losses, and ensuring reliable temperature measurement.

EQUATION

—-----------------------------------------------------------------

Specific Heat Capacity (ΔE = mcΔT)

ΔE = Energy transferred to the material (J)

m = Mass of the substance (kg)

c = Specific heat capacity (J kg⁻¹ K⁻¹)

ΔT = Temperature change (K or °C)

—-----------------------------------------------------------------

Electrical Heating Method Overview

The electrical method provides a controlled and measurable way of transferring energy to a sample. It relies on Joule heating, where an electric current passes through a resistor or heating coil, releasing thermal energy into the material.

EQUATION

—-----------------------------------------------------------------

Electrical Energy Supplied (E = IVt)

E = Energy transferred by heating (J)

I = Current through the heater (A)

V = Potential difference across the heater (V)

t = Heating time (s)

—-----------------------------------------------------------------

To find c, both ΔE and ΔT must be measured accurately. This requires careful setup for metals and liquids, as their physical properties differ significantly.

Techniques for a Metal Block

Apparatus and Setup

A typical arrangement includes:

A metal block (usually aluminium or copper) with two drilled holes—one for a thermometer and one for an immersion heater.

An ammeter, voltmeter, and timer to record electrical quantities.

Insulation material (such as expanded polystyrene or felt) wrapped around the block to reduce heat loss.

Procedure

Measure and record the mass of the metal block using a balance.

Insert the immersion heater and thermometer securely into the block’s holes.

Insulate the block to minimise heat loss to the environment.

Record the initial temperature.

Switch on the power supply and allow current to flow through the heater for a measured time.

Record current (I), potential difference (V), and heating time (t).

Monitor temperature and note the final value after switching off the heater.

Calculate the temperature change ΔT.

Determine c using the equations for ΔE and ΔT.

Accuracy Considerations

Ensure good thermal contact between heater and block to improve heat transfer efficiency.

Use small current and moderate heating time to prevent significant heat loss during the experiment.

Extrapolate temperature–time graphs to account for heat loss before and after heating.

Polish and dry the block before use to avoid errors from surface moisture or oxidation.

Techniques for a Liquid

Apparatus and Setup

Liquids present additional challenges due to convection currents and container heat capacity.

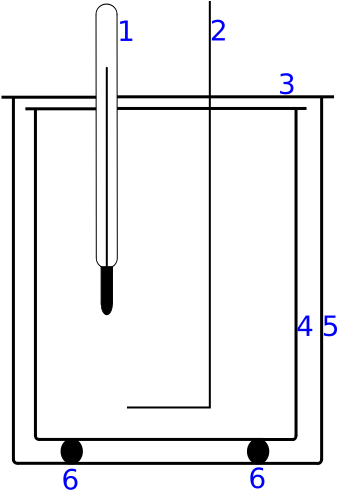

Schematic of a calorimeter for liquids, showing the insulated vessel, lid, and thermometer to reduce heat exchange with the surroundings. This emphasises why experiments must correct for the calorimeter’s own heat capacity (m₂c₂ΔT term). Extra detail: the image depicts a generic calorimeter without the immersion heater drawn; in practice the heater is inserted through the lid. Source.

The apparatus typically includes:

A calorimeter (often copper) containing the liquid sample.

An immersion heater placed centrally in the liquid.

A thermometer or temperature sensor inserted into the liquid.

An insulating jacket around the calorimeter to reduce energy loss.

Electrical instruments (ammeter, voltmeter, timer) as before.

Procedure

Measure the mass of the empty calorimeter and then the calorimeter with liquid to determine mass of the liquid.

Assemble the apparatus ensuring the heater and thermometer are fully submerged but not touching the container walls.

Insulate the calorimeter carefully.

Record the initial temperature.

Switch on the heater and maintain a steady current for a fixed period.

Record I, V, and t throughout the heating period.

Monitor the rise in temperature and record the final temperature.

Account for the calorimeter’s own heat capacity when calculating c for the liquid.

EQUATION

—-----------------------------------------------------------------

Energy Balance for Liquid (IVt = m₁c₁ΔT + m₂c₂ΔT)

IVt = Electrical energy supplied (J)

m₁ = Mass of the liquid (kg)

c₁ = Specific heat capacity of the liquid (J kg⁻¹ K⁻¹)

m₂ = Mass of the calorimeter (kg)

c₂ = Specific heat capacity of the calorimeter material (J kg⁻¹ K⁻¹)

ΔT = Temperature change (K or °C)

—-----------------------------------------------------------------

This equation allows for correction due to energy absorbed by the calorimeter.

Accuracy Considerations

Stir the liquid gently to ensure uniform temperature distribution.

Use a digital thermometer for higher precision.

Allow the liquid to cool gradually after heating and record cooling data for correction graphs.

Avoid evaporation losses, particularly for volatile liquids, by using lids or covering films.

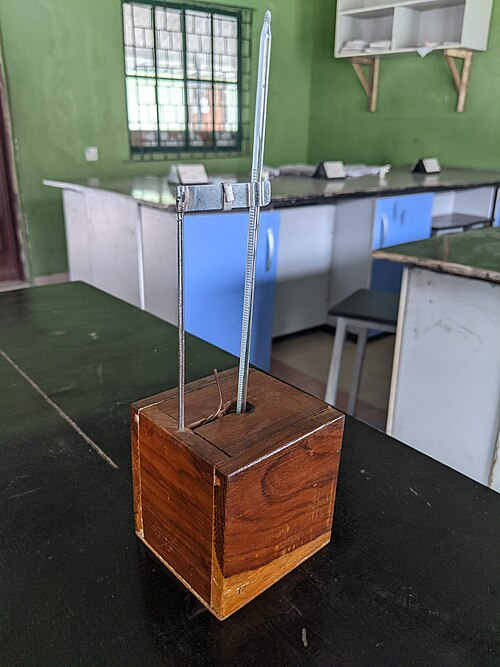

A copper calorimeter with outer insulation, used for specific heat capacity measurements of liquids. Its construction minimises heat loss to improve the accuracy of E = IVt = m₁c₁ΔT + m₂c₂ΔT analyses. Extra detail: the wooden case is an insulating accessory not explicitly required by the syllabus but useful for reducing systematic losses. Source.

Sources of Error and Minimisation Techniques

To ensure valid results, students must recognise and reduce sources of systematic and random error:

Heat losses to surroundings:

Minimise using insulation, lid covers, and short heating durations.

Energy absorbed by apparatus:

Correct using calorimeter heat capacity.

Inaccurate electrical readings:

Use calibrated meters and take mean readings.

Poor temperature measurement:

Avoid thermometer lag; ensure full thermal contact.

Uneven heating in liquids:

Stir to prevent local temperature gradients.

Assuming constant power supply:

Check for voltage fluctuation during heating.

Careful design, accurate measurement, and effective corrections improve the determination of specific heat capacity for both metals and liquids.

Practical Skill Emphasis

This experiment integrates multiple practical competencies required by OCR:

Planning: selecting apparatus and insulation methods.

Measurement: accurate timing, electrical readings, and temperature monitoring.

Data handling: applying energy equations and considering uncertainties.

Evaluation: discussing sources of error and reliability of results.

Mastery of these techniques enables students to perform precise thermal experiments, reinforcing understanding of energy transfer and material properties within Thermal Physics.

FAQ

Metals such as aluminium, copper, and brass are often used because they have uniform density, known specific heat capacities, and good thermal conductivity.

High conductivity ensures even heat distribution throughout the block, which reduces temperature gradients and measurement errors.

Additionally, these metals are easy to machine, allowing precise holes to be drilled for the heater and thermometer, improving thermal contact and repeatability in experiments.

Thermal equilibrium ensures that all parts of the material are at the same temperature before measurements are taken.

If the heater and thermometer are not in equilibrium with the metal or liquid, localised heating occurs, leading to inaccurate temperature changes (ΔT).

Allowing equilibrium stabilises readings and ensures that the measured ΔT reflects the true average temperature rise of the entire sample rather than one local region.

One method is to plot a temperature–time graph for both heating and cooling phases.

Extrapolate the cooling curve backward to estimate the temperature the material would have reached with no heat loss.

The difference between this extrapolated temperature and the observed maximum helps correct for energy lost to the surroundings.

This technique improves accuracy, particularly in longer experiments where losses by convection and radiation are significant.

Electrical methods assume all electrical energy converts to internal energy, while mechanical methods (e.g. friction-based heating) may introduce additional variables.

Mechanical methods can suffer from uneven force application or kinetic energy losses to vibration and sound.

Electrical methods allow more precise energy input measurement using current, voltage, and time, but still depend on good insulation and accurate calibration.

Differences often highlight how energy losses and measurement precision affect practical results rather than the intrinsic property of the material.

Safety is crucial because experiments involve mains-powered heaters, hot equipment, and liquids.

Use low-voltage DC supplies through laboratory power packs to minimise electric shock risk.

Ensure heaters are fully immersed in liquids or securely fitted into solids to prevent overheating.

Avoid touching hot blocks or calorimeters; use heatproof gloves or tongs.

Keep all electrical components dry and avoid water spillage around power leads.

These precautions protect both the user and equipment during high-temperature and electrical measurements.

Practice Questions

Question 1 (2 marks)

A student heats a 0.80 kg copper block using an electrical heater supplied with a current of 3.0 A at 12 V for 300 s. The temperature of the block rises by 15 °C.

(a) Calculate the specific heat capacity of the copper block.

(b) State one assumption made in this calculation.

Mark Scheme

(a)

Energy supplied = IVt = 3.0 × 12 × 300 = 10 800 J (1 mark)

Specific heat capacity = E / (mΔT) = 10 800 / (0.80 × 15) = 900 J kg⁻¹ K⁻¹ (1 mark)

(b)

Any one of:

All electrical energy is transferred to the block (no heat loss).

The block is heated uniformly.

No energy absorbed by the heater or leads.

(1 mark – accept any valid assumption, max 1 mark total)

Question 2 (5 marks)

In an experiment to determine the specific heat capacity of water, a student uses an immersion heater placed in an insulated copper calorimeter containing 0.20 kg of water. The heater is supplied with 2.5 A at 12.0 V for 240 s. The mass of the copper calorimeter is 0.080 kg and its specific heat capacity is 390 J kg⁻¹ K⁻¹. The temperature rise of the water and calorimeter is 10.0 °C.

(a) Write the energy balance equation used in this experiment.

(b) Calculate the specific heat capacity of water.

(c) Suggest and explain two practical improvements that would reduce the uncertainty in this measurement.

Mark Scheme

(a)

IVt = (m₁c₁ + m₂c₂)ΔT (1 mark)

(b)

Substitute:

30 000 = (0.20 × c₁ + 0.080 × 390) × 10 (1 mark)

30 000 = (2.0c₁ + 312) (1 mark)

c₁ = (30 000 − 312) / 2.0 = 14 844 J kg⁻¹ K⁻¹ (1 mark)

Rounded to 1.48 × 10⁴ J kg⁻¹ K⁻¹ (accept 1.5 × 10⁴ J kg⁻¹ K⁻¹) (1 mark)

(c)

Any two improvements (1 mark each):

Use a lid to reduce heat loss by convection/evaporation.

Stir the water gently to ensure uniform temperature.

Use a digital thermometer or data logger for smaller reading uncertainty.

Improve insulation around the calorimeter to reduce energy losses.