AP Syllabus focus:

'Post-Fordist production methods have transformed industry through flexible specialization and globally dispersed production networks.'

Industrial production shifted dramatically in the late twentieth century as firms replaced rigid assembly-line systems with flexible, networked, and globally distributed methods that respond rapidly to changing markets.

Post-Fordism in Context

Post-Fordism refers to a broad transformation in industrial organization that followed the decline of Fordism, the mass-production system built on standardized products, large factories, and long production runs.

This 1913 photograph shows workers on a Ford motor company moving assembly line, illustrating the highly standardized, repetitive labor typical of Fordist mass production. The image helps students contrast large, centralized factories with the more flexible, decentralized arrangements that characterize Post-Fordist production. It adds historical detail on early manufacturing that goes slightly beyond the AP syllabus but directly supports understanding of what Post-Fordism reacted against. Source.

As global competition increased and consumer preferences diversified, firms required more adaptable forms of production. Post-Fordism emerged as a response, emphasizing flexibility, innovation, and specialized production networks over the rigid structures of earlier manufacturing.

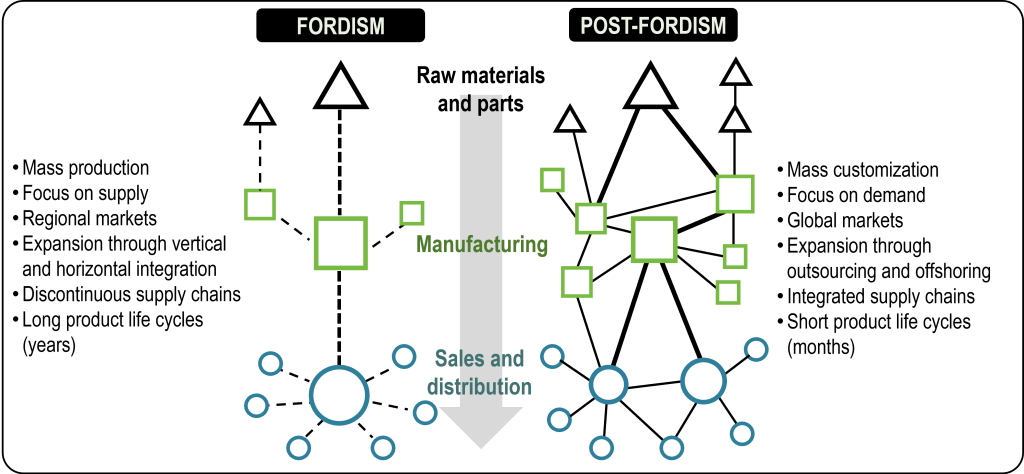

This diagram contrasts a Fordist production system, with a simple, vertically organized flow from raw materials to distribution, with a Post-Fordist system composed of dense, interconnected networks. It illustrates how Post-Fordism replaces rigid, linear chains with flexible relationships among multiple firms and production stages. The diagram includes minor logistical details beyond the AP syllabus but supports understanding of networked production. Source.

Key Features of Post-Fordist Production

Post-Fordist production is defined by characteristics that contrast sharply with Fordist mass production.

Flexible Specialization

Flexible specialization is the ability of firms to rapidly shift production processes, product designs, or output levels in response to new market demands. This practice is supported by advanced technologies and decentralized systems that allow firms to modify tasks quickly without halting entire production lines.

Flexible Specialization: A production approach in which firms adapt rapidly to shifting consumer preferences by using adaptable technologies, smaller batch sizes, and skilled labor.

Firms use flexible strategies because global markets increasingly reward product variety, rapid innovation cycles, and the ability to deliver customized goods.

Decentralization of Work

Post-Fordism reduces the dominance of massive, centralized factories by dispersing production among multiple smaller facilities or contracted partners. This decentralization encourages:

Collaborative production across different regions

Greater autonomy for local units

Faster adaptation to technological change

Reduced risks associated with maintaining large, fixed industrial plants

Decentralization also supports the geographic spread of production networks across national borders, reinforcing the global dimension of Post-Fordism.

Skilled Labor and New Work Roles

Under Post-Fordist practices, workers often require broader and more specialized skills than in Fordist assembly lines. Instead of performing repetitive, narrowly defined tasks, workers frequently engage in:

Problem-solving

Quality control

Coordination within team-based systems

Operation of programmable machines

This shift encourages the growth of a more flexible workforce capable of operating in technologically dynamic environments.

The Role of Technology in Post-Fordist Systems

Post-Fordism depends heavily on digital technologies that enable rapid communication, real-time adjustments, and global coordination.

Information Technologies

Technologies such as computer-aided design, robotics, enterprise management software, and telecommunications have reshaped production by:

Integrating suppliers and manufacturers through shared digital platforms

Supporting just-in-time logistics

Enabling small-batch customization

Reducing errors and waste

Digital connectivity makes it possible to coordinate dispersed production facilities as if they were part of a single system.

Automation and Robotics

Automation supports Post-Fordist flexibility by allowing machines to be reprogrammed quickly for new tasks. Unlike fixed Fordist equipment designed for one product, Post-Fordist machinery enables:

Frequent product redesign

Rapid switching between production lines

Reduced labor costs in routine tasks

Enhanced precision and efficiency

These capabilities allow firms to innovate without major interruptions.

Global Production Networks

One of the defining elements of Post-Fordism is the creation of globally dispersed production networks, in which various stages of manufacturing occur in different countries.

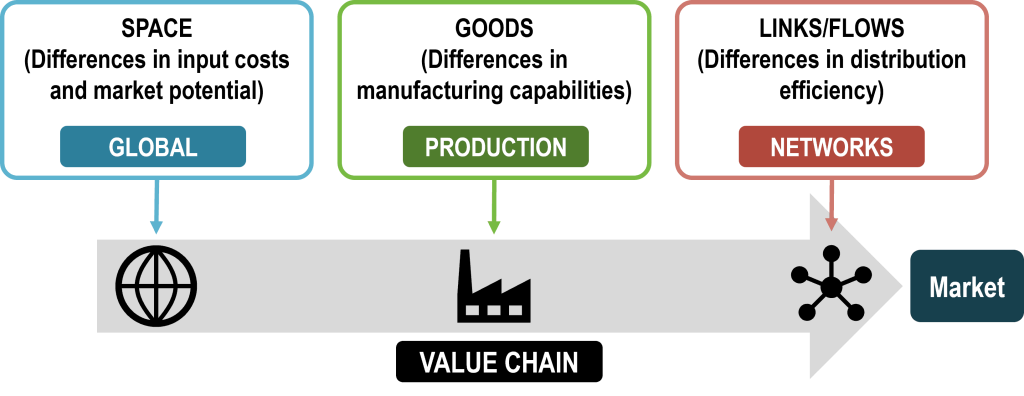

This diagram presents a global production network, linking inputs, transformation, distribution, and consumption across multiple locations. It visually supports the concept of geographically dispersed production central to Post-Fordism. The image includes extra detail on financial and technological inputs beyond the AP syllabus but enhances understanding of networked production systems. Source.

Characteristics of Global Networks

Firms distribute production tasks based on comparative advantages in labor, technology, and logistics. This approach generates:

International subcontracting

Specialized suppliers in multiple regions

Cross-border flows of components

Dependency on efficient transportation and communication systems

The result is a web of interconnected production sites that can adjust output and collaborate across long distances.

Outsourcing and Supplier Integration

Many firms outsource tasks such as assembly, component production, or logistics to independent companies within their networks. This practice reduces fixed costs and promotes innovation by allowing firms to tap into specialized expertise.

Spatial Implications of Post-Fordist Production

Post-Fordism strongly influences the geography of industry and the distribution of labor.

Industrial Dispersal

The decline of large, single-site factories has encouraged production to spread across metropolitan regions, smaller urban centers, and international locations. This dispersal is shaped by:

Access to specialized labor pools

Proximity to research institutions

Infrastructure that supports rapid mobility

Government incentives promoting investment

New Regional Economies

Certain regions develop clusters of firms and suppliers that reinforce each other’s growth. These clusters benefit from:

Agglomeration effects, the advantages firms gain from locating near one another

Shared knowledge and innovation

Localized networks of skilled labor

Such regions can evolve into high-technology corridors or advanced manufacturing hubs.

Shifts in Consumer and Firm Relationships

Post-Fordist production aligns closely with markets that value customization and rapid product turnover. Firms differentiate their goods through design, branding, and technological innovation. This environment encourages:

Shorter product life cycles

Constant innovation

Continuous feedback between consumers and producers

Market segmentation based on varied needs

These shifts reinforce the demand for flexible, adaptive industrial systems.

Post-Fordism and Economic Development

Post-Fordist production contributes to new patterns of global development by enabling countries with technological capabilities and skilled labor to attract advanced manufacturing. At the same time, regions specializing in routine tasks remain tied to earlier forms of industrialization. The resulting landscape includes sophisticated innovation centers linked to wide networks of lower-cost production sites, illustrating how flexibility and global connectivity define modern economic systems.

FAQ

Knowledge transfer allows firms within a cluster to share innovations, technical skills, and market insights.

It occurs through:

Labour mobility between firms

Supplier–client interactions

Collaboration with research institutions

These exchanges make clusters more adaptive, supporting rapid innovation cycles that align with Post-Fordist flexibility.

Workers often face more varied and team-based responsibilities, with increased emphasis on communication and problem-solving.

However, flexible production can also create employment instability:

Project-based contracts

Demand-driven scheduling

Greater reliance on subcontracted labour

This duality means workers may gain autonomy and skill development while also experiencing less predictable employment patterns.

Flexible and dispersed production requires components and information to move quickly between geographically separated sites.

Efficient logistics enable just-in-time delivery, reduce inventory storage costs, and help firms adapt output in response to shifting market conditions.

As a result, regions with strong transport infrastructure become strategic nodes in Post-Fordist networks, attracting investment and specialised suppliers.

Consumers increasingly demanded greater product variety, faster updates, and customisation, making rigid mass-production systems less effective.

This pushed firms to adopt flexible manufacturing, shorter production runs, and rapid product development cycles.

Post-Fordism therefore reflects an adaptation to markets where differentiation and speed became more profitable than uniformity.

SMEs often specialise in niche components or services, allowing them to operate as agile partners within wider production networks.

They support innovation by developing specialised technologies or processes and can respond quickly to design changes from larger firms.

Because they cluster in certain regions, SMEs also help create localised networks of expertise that strengthen regional competitiveness.

Practice Questions

Question 1 (1–3 marks)

Explain one way in which Post-Fordist production differs from Fordist production.

Question 1

Award up to 3 marks for a clear distinction between Post-Fordist and Fordist production.

1 mark for a basic statement identifying a difference (e.g., Post-Fordism is flexible, Fordism is standardised).

2 marks for adding brief development (e.g., noting that Post-Fordism involves smaller batch sizes or rapid adjustments).

3 marks for a fully developed explanation that includes a contrasting element for both systems (e.g., Post-Fordism uses flexible, decentralised production networks, whereas Fordism relies on rigid, centralised assembly-line work).

Question 2 (4–6 marks)

Using specific geographic reasoning, analyse how globally dispersed production networks contribute to the spatial restructuring of industry in the Post-Fordist era.

Question 2

Award marks based on the depth and accuracy of geographic reasoning.

1–2 marks for a general description of global production networks or dispersed manufacturing.

3–4 marks for explanation of how these networks reshape industrial geography, such as through decentralisation, outsourcing, or the rise of new regional clusters.

5–6 marks for a well-developed analysis using geographic concepts (e.g., comparative advantage, agglomeration, shifting labour markets, or core–periphery dynamics) that clearly links dispersed production with spatial industrial restructuring.