OCR Specification focus:

‘Relate power, energy, and efficiency when comparing electrical devices.’

Efficiency in electrical systems compares useful energy output to total energy input, revealing how effectively a device converts supplied power into the desired form of energy.

Understanding Efficiency in Electrical Devices

In all electrical systems, energy is transferred, transformed, and often wasted as heat, sound, or light. Efficiency provides a quantitative measure of how well a device performs its intended energy conversion.

Efficiency: The ratio of useful energy or power output to total energy or power input, expressed as a percentage or decimal fraction.

Efficiency highlights both engineering quality and energy conservation. A perfectly efficient device (100%) would convert all input energy into useful output without losses, but such perfection is physically impossible due to unavoidable energy dissipation.

Power and Energy Relationships

Electrical devices convert energy at a rate defined as power, the rate of energy transfer or work done per unit time.

EQUATION

—-----------------------------------------------------------------

Electrical Power (P) = V × I

P = Power (watts, W)

V = Potential difference (volts, V)

I = Current (amperes, A)

—-----------------------------------------------------------------

Electrical power can also be related to current and resistance:

EQUATION

—-----------------------------------------------------------------

Power (P) = I²R = V² / R

R = Resistance (ohms, Ω)

—-----------------------------------------------------------------

Energy transfer over time builds upon this relationship, connecting total energy output to power and duration of operation. Devices with greater power ratings convert more energy per second but may not necessarily do so efficiently.

Defining Efficiency Quantitatively

Efficiency can be expressed in terms of energy or power, as the ratio of useful output to total input.

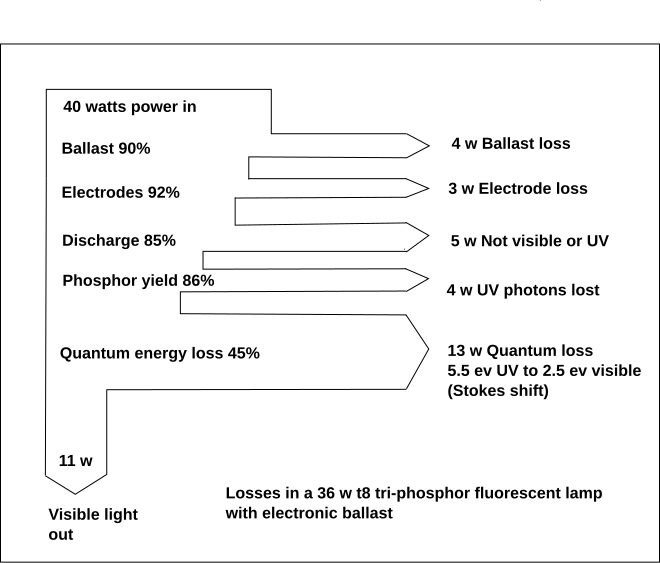

A Sankey diagram showing a fluorescent lamp’s energy flows: the horizontal arrow represents useful light and the downward arrow represents wasted heat. The widths are proportional to energy, reinforcing the definition of efficiency. Extra lamp-specific percentages shown exceed OCR’s minimum, but the diagram’s structure is directly applicable to any device. Source.

EQUATION

—-----------------------------------------------------------------

Efficiency (η) = Useful output energy ÷ Total input energy

= Useful output power ÷ Total input power

η = Efficiency (no units, often expressed as a %)

—-----------------------------------------------------------------

The result is typically multiplied by 100 to express efficiency as a percentage. For instance, an efficiency of 0.85 means 85% of the input energy is usefully employed, while 15% is lost.

Between these two forms (energy and power), the ratio remains the same because energy transfer over time is proportional to power.

Sources of Energy Loss

Even well-designed electrical devices experience unavoidable losses. Understanding these helps identify improvement opportunities.

Common energy losses include:

Joule heating: Resistance in conductors and components converts electrical energy into heat.

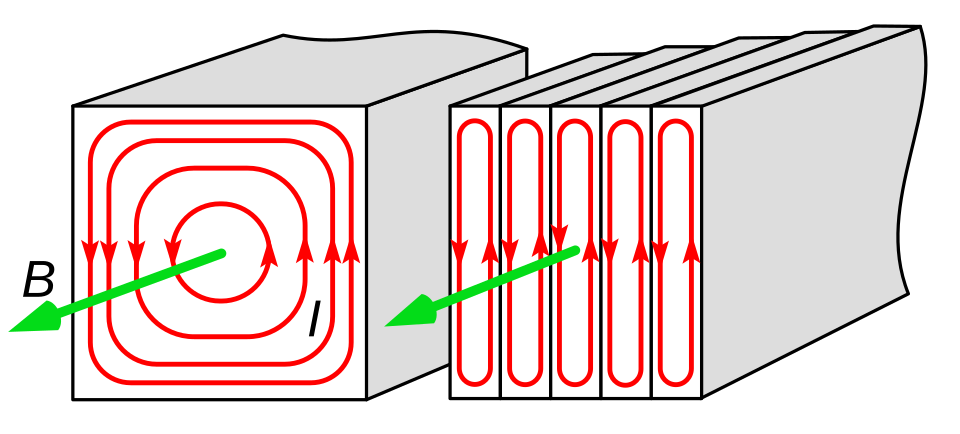

Magnetic losses: In motors and transformers, changing magnetic fields cause eddy currents and hysteresis losses.

Diagram comparing a solid transformer core (left) to a laminated core (right). Laminations confine circulating eddy currents to tiny loops, reducing I²R heating and improving efficiency. The magnetic field and current loops are shown schematically; detailed material physics is beyond the OCR scope. Source.

Mechanical friction: In moving devices such as fans or generators, friction dissipates energy as heat or sound.

Radiative losses: Light bulbs or displays emit unwanted light or infrared radiation.

Leakage currents: Small, unwanted currents that bypass intended paths, reducing useful output.

Reducing these losses increases efficiency and reduces energy costs, contributing to both economic and environmental benefits.

Comparing Efficiencies Across Devices

Efficiency is not uniform across electrical systems. When comparing devices, the purpose and operating conditions must be considered.

For example:

Incandescent bulbs have efficiencies below 10% since most energy becomes heat rather than visible light.

LEDs achieve 30–40% efficiency, converting a greater portion into visible light.

Electric motors often exceed 90% efficiency due to design improvements in materials and cooling.

Transformers in power networks can approach 99% efficiency when engineered to minimise resistive and magnetic losses.

Such comparisons highlight that high efficiency corresponds to low energy wastage, improved performance, and reduced operational costs.

Relationship Between Power, Energy, and Efficiency

The interplay between power, energy, and efficiency defines a device’s overall performance. The total energy output depends on both power and operating time, but the proportion of useful output is limited by efficiency.

EQUATION

—-----------------------------------------------------------------

Useful Energy Output = Efficiency × Total Energy Input

—-----------------------------------------------------------------

EQUATION

—-----------------------------------------------------------------

Useful Power Output = Efficiency × Total Power Input

—-----------------------------------------------------------------

These equations show that efficiency directly scales the effective energy or power delivered for practical work.

For example, two machines with identical power ratings may deliver different useful outputs if one has superior efficiency. Engineers use this relationship to design devices that provide maximum output for minimal energy consumption.

Improving Electrical Efficiency

Enhancing efficiency requires reducing energy losses through thoughtful design and component selection.

Strategies for improvement include:

Using conductors with low resistivity, such as copper or aluminium, to minimise Joule heating.

Applying superconducting materials in specialised systems to eliminate resistance losses entirely.

Improving insulation to prevent unwanted heat loss in appliances.

Utilising switching circuits and semiconductors that reduce energy waste in control systems.

Adopting energy-efficient power supplies, such as switch-mode regulators, which minimise conversion losses.

Optimising mechanical design, using lubrication and precision alignment to reduce frictional losses.

These measures enhance both device performance and energy sustainability.

Efficiency in Context: Consumer and Environmental Relevance

Efficiency extends beyond technical considerations to societal and environmental impacts. Energy-efficient devices reduce demand on electricity generation, thereby lowering carbon emissions and energy costs.

Consumers often use energy efficiency labels to inform purchase decisions.

At scale, efficient technologies support sustainable development goals, enabling reduced waste and improved energy management within homes, industries, and transport systems.

Practical Evaluation of Efficiency

Students and engineers can determine efficiency through measurements of input and output energy or power. In experiments:

Measure input voltage and current to calculate total input power.

Measure output energy form (e.g. mechanical work, light intensity, or heat) to find useful power.

Calculate efficiency using the standard formula.

Careful data logging and uncertainty analysis ensure reliability and repeatability of efficiency determinations. This practice reflects real-world engineering testing, where efficiency benchmarks validate device performance and inform design revisions.

By relating power, energy, and efficiency, students gain a deeper understanding of how physical principles translate into technological applications, meeting the OCR requirement to compare electrical devices effectively.

FAQ

Temperature can significantly reduce efficiency because increased temperature raises the resistance of most conductors, leading to greater energy losses as heat.

In components such as resistors or motor coils, this heat not only wastes energy but can also lower the voltage delivered to the load.

To maintain high efficiency, electrical devices often use cooling systems, heat sinks, or ventilation to manage temperature and reduce resistive heating.

No device can be perfectly efficient because energy conversions always involve unavoidable losses. These are dictated by the laws of thermodynamics and material properties.

Even with ideal conductors, other forms of loss occur, such as:

Friction in moving parts

Sound or vibration energy

Radiation or magnetic hysteresis losses

Thus, some portion of input energy is always dissipated as unusable heat or other forms.

Efficiency is determined by measuring input and output power under controlled conditions.

Common steps include:

Measuring input voltage and current using meters to calculate total input power.

Measuring useful output energy, such as mechanical work, light intensity, or torque.

Using data-logging equipment to ensure consistent readings and reduce human error.

Engineers repeat tests under different loads and temperatures to build an efficiency curve showing performance across real operating conditions.

Electric motors can be made more efficient through a combination of mechanical and electromagnetic design choices:

Laminated cores reduce eddy current losses.

High-permeability materials minimise magnetic hysteresis losses.

Precision bearings and lubrication cut down mechanical friction.

Improved winding geometry ensures more effective use of the magnetic field.

Advanced control electronics can also optimise the timing and shape of current flow to further improve conversion efficiency.

Higher efficiency means that less energy is wasted, reducing the demand for electricity generation and lowering greenhouse gas emissions.

For consumers, efficient devices translate to lower electricity bills and longer component lifetimes.

On a larger scale, improving national energy efficiency helps reduce strain on power grids, supports renewable integration, and aligns with environmental regulations promoting carbon neutrality.

Practice Questions

Question 1 (2 marks)

An electric kettle has a power input of 2.0 kW and an efficiency of 80%.

Calculate the useful power output of the kettle. State your answer with the correct unit.

Mark scheme:

Correct substitution into the efficiency equation: efficiency = useful output power ÷ total input power (1 mark)

Correct calculation and unit: 0.8 × 2000 = 1600 W or 1.6 kW (1 mark)

Question 2 (5 marks)

An engineer designs a small electric motor for use in a model car. The motor is supplied with an electrical power input of 12 W and produces a useful mechanical power output of 9 W.

(a) Calculate the efficiency of the motor. (2 marks)

(b) State two possible reasons why the motor is not 100% efficient. (2 marks)

(c) Suggest one design change that could improve the efficiency of the motor, explaining why it would help. (1 mark)

Mark scheme:

(a)

Correct use of efficiency formula: efficiency = (useful output ÷ total input) × 100 (1 mark)

Correct calculation: (9 ÷ 12) × 100 = 75% (1 mark)

(b)

Any two from:

Some energy is lost as heat due to resistance in the coils (Joule heating) (1 mark)

Friction between moving parts produces unwanted heat and sound (1 mark)

Eddy current or magnetic losses in the core (1 mark, maximum of 2)

(c)

Any one valid suggestion with reason:

Use lubrication to reduce friction (1 mark)

Use a laminated iron core to reduce eddy current losses (1 mark)

Use thicker or lower-resistance wire to reduce heating losses (1 mark)

(Maximum 1 mark)