OCR Specification focus:

‘Use a range of practical equipment safely, identify potential hazards, and explain risk minimisation strategies in laboratory settings.’

Safe use of laboratory equipment ensures accurate results and protects individuals from harm. Understanding potential hazards and effective risk management is fundamental to all experimental work in physics.

Safe Use of Equipment in Physics Laboratories

Working safely in a physics laboratory requires both technical competence and awareness of potential risks. Every piece of equipment, from a simple thermometer to a high-voltage power supply, presents possible dangers if used incorrectly. A physics student must demonstrate not only proficiency in handling apparatus but also a clear understanding of safety procedures, risk assessment, and control measures.

Common Categories of Laboratory Equipment

Laboratory equipment in physics can be broadly grouped into several categories, each with specific safety requirements:

Electrical equipment – includes power supplies, multimeters, and circuit components.

Thermal apparatus – such as heaters, Bunsen burners, or temperature sensors.

Mechanical devices – including trolleys, pulleys, and force meters.

Optical instruments – like lasers, lenses, and mirrors.

Measurement tools – including micrometers, vernier calipers, and balances.

Each type of apparatus requires safe setup, careful handling, and correct shutdown procedures to minimise risks.

Recognising and Managing Hazards

What is a Hazard?

Hazard: Anything with the potential to cause harm, such as electricity, sharp edges, heat, radiation, or chemical substances.

A hazard becomes dangerous when it interacts with people, materials, or the environment in unsafe ways. In a laboratory, hazards often relate to energy sources or equipment misuse.

Examples include:

Electrical hazards: risk of electric shock from exposed wires or incorrect connections.

Thermal hazards: burns from hot equipment or liquids.

Mechanical hazards: injury from moving apparatus or collapsing stands.

Radiation hazards: exposure to ionising sources during nuclear experiments.

Optical hazards: eye damage from lasers or bright light.

Identifying Hazards Before Practical Work

Students must conduct a risk assessment before carrying out experiments. This process ensures all hazards are recognised and suitable controls are in place.

Steps in hazard identification:

Inspect equipment for damage, frayed wires, or loose connections.

Review the experimental setup to detect unsafe configurations.

Consider the working environment, such as trip hazards, spills, or confined spaces.

Predict possible malfunctions, for example overheating or short circuits.

Risk Management and Minimisation

Understanding Risk

Risk: The likelihood that a hazard will cause harm, combined with the severity of the potential outcome.

A key goal of laboratory safety is to reduce risk to an acceptable level. While not all hazards can be eliminated, most can be controlled through careful planning.

Hierarchy of Risk Control

When minimising risk, the hierarchy of control provides a structured approach:

Elimination – remove the hazard entirely if possible.

Example: using a low-voltage source instead of mains electricity.Substitution – replace with a less hazardous alternative.

Example: using a light-emitting diode instead of a laser.Engineering controls – design setups that reduce exposure.

Example: use of protective shields or guards.Administrative controls – establish safe procedures and training.

Example: providing written instructions and supervision.Personal protective equipment (PPE) – last line of defence.

Example: wearing safety goggles or heat-resistant gloves.

Personal Protective Equipment (PPE)

PPE must always be appropriate for the task.

Standardised ISO 7010 M007 safety sign indicating mandatory eye protection. Use in laboratory areas where eye hazards are present from projectiles, splashes, or optical sources. This symbol matches widely adopted international signage and does not introduce content beyond the syllabus. Source.

Common examples include:

Safety goggles – protect eyes from debris, radiation, or chemicals.

Lab coats – prevent contact with hot substances or electrical sparks.

Gloves – provide insulation from heat, chemicals, or electrical current.

Closed shoes – protect feet from dropped objects or spills.

Electrical Safety in the Laboratory

Electricity is a core component of many physics experiments, making electrical safety vital.

Key precautions include:

Never handling equipment with wet hands.

Checking that cables are intact and connections secure.

Using fused plugs and low-voltage supplies whenever possible.

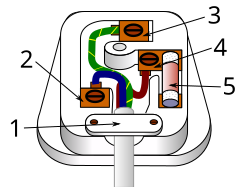

Labelled diagram of a British 3-pin mains plug (BS 1363) showing live, neutral, earth, and an internal fuse. The earth provides a low-resistance path to ground if a fault energises the casing, reducing shock risk. This directly illustrates best practice for school laboratory electrical safety. Source.

Ensuring circuits are correctly wired before energising.

Disconnecting apparatus after use and when adjusting components.

Earth connection: A safety feature that provides a low-resistance path to ground, preventing electric shock from metal casings if a fault occurs.

Thermal and Mechanical Safety

Experiments involving heat sources require strict attention. Burns and fires are common risks if materials or methods are mishandled.

Safety considerations:

Allow hot apparatus to cool before touching or storing.

Keep flammable materials away from open flames or heaters.

Never leave heating equipment unattended.

Use tongs or heatproof mats to handle heated items.

Mechanical systems, such as trolleys and pendulums, carry impact and crushing risks.

To minimise these:

Secure stands and clamps firmly.

Ensure weights and pulleys are balanced and aligned.

Avoid placing body parts in the path of moving objects.

Radiation and Optical Safety

When using ionising radiation, strict controls are required.

Key procedures:

Use only sealed sources approved for educational use.

Minimise exposure time and maintain distance from the source.

Employ lead shielding or designated barriers.

Store sources in locked containers when not in use.

For optical hazards, such as lasers:

Never look directly into the beam.

Avoid reflective surfaces near the path of light.

Use low-power lasers (Class 1 or 2) for student experiments.

Ionising radiation: Radiation that has enough energy to remove electrons from atoms, creating ions; examples include alpha, beta, and gamma radiation.

Conduct, Documentation, and Responsibility

Safe use of equipment depends on discipline and communication. Each person in the lab shares responsibility for maintaining a safe environment.

Good practice includes:

Following teacher or supervisor instructions carefully.

Reporting faulty or damaged equipment immediately.

Keeping work areas tidy and uncluttered.

Recording any incidents or near misses in the safety log.

Ensuring all equipment is switched off and stored safely after use.

Understanding and applying these principles ensures that practical physics remains both safe and scientifically valid, supporting the goals of the OCR A-Level Physics practical endorsement.

FAQ

A hazard is anything that has the potential to cause harm — for example, electricity, heat, or moving machinery.

A risk refers to how likely it is that the hazard will actually cause harm and how severe that harm could be.

For instance, a Bunsen burner is a hazard because it produces heat, but the risk increases if flammable materials are nearby or if safety precautions are ignored. Managing risk involves evaluating both the likelihood and severity of possible outcomes.

A structured approach ensures risks are properly controlled:

Identify hazards associated with the apparatus and materials.

Assess risks by considering likelihood and severity.

Determine control measures such as PPE, supervision, or modified procedures.

Implement controls before starting the experiment.

Review and update the assessment if conditions change.

In an A-Level setting, this process is typically recorded briefly in the planning section of the student’s practical log or investigation write-up.

Poorly calibrated instruments can lead to incorrect readings that cause unsafe conditions — for example, overheating, overvoltage, or misjudged forces.

Ensuring calibration helps maintain accurate control of variables and prevents apparatus from operating outside safe limits.

Before each practical session:

Check zero readings on balances or voltmeters.

Verify temperature sensors against known references.

Confirm mechanical scales move freely and read consistently.

Accurate calibration is therefore both a safety measure and a requirement for experimental reliability.

Before energising any circuit or apparatus:

Inspect cables for fraying or exposed wires.

Ensure all connections are secure and correctly polarised.

Confirm the circuit design matches the intended diagram.

Check that any fuse ratings are appropriate for the current expected.

Make sure the bench and area are dry and clutter-free.

Performing these checks prevents short circuits, overheating, and accidental shocks — common causes of laboratory incidents.

Immediate and accurate reporting is essential.

Stop the experiment and make the area safe — switch off power, remove heat sources, or isolate the hazard.

Inform a supervisor or teacher straight away.

Provide first aid if trained and it’s safe to do so.

Record the incident in the laboratory safety log, noting cause and response.

Near misses are just as important to report because they highlight weaknesses in procedure or equipment that could lead to future accidents if ignored.

Practice Questions

Question 1 (2 marks)

In a physics laboratory, a student notices that the insulation on a wire connected to a power supply is damaged.

(a) State one potential hazard associated with this situation.

(b) Describe one immediate action the student should take to reduce risk.

Mark scheme:

(a) 1 mark for identifying an appropriate hazard:

Risk of electric shock (1)

Risk of short circuit or fire (1)

(b) 1 mark for a correct action to reduce risk:

Turn off and unplug the power supply before touching the wire (1)

Report the fault to a supervisor or teacher (1)

Replace or repair the cable before continuing the experiment (1)

Maximum 2 marks.

Question 2 (5 marks)

A student is setting up an experiment using a heater to warm water in a metal container. The experiment involves temperature measurement with a thermometer.

Discuss the main hazards and risk management strategies the student should consider to ensure safe use of the equipment.

Mark scheme:

Award 1 mark per valid point, up to a maximum of 5 marks.

Identification of hazards (up to 3 marks):

Risk of burns from hot water or metal container (1)

Risk of electric shock from the heater if water spills on electrical parts (1)

Risk of spillage causing slips or other injuries (1)

Risk management and minimisation strategies (up to 3 marks):

Use heatproof mats, tongs, or gloves to handle hot items (1)

Keep electrical connections dry and ensure the heater is properly insulated (1)

Position apparatus securely on a stable surface to avoid tipping or spillage (1)

Allow cooling time before dismantling or touching equipment (1)

Indicative content for full marks:

Student identifies at least two significant hazards and outlines appropriate control measures showing clear understanding of risk management principles (e.g. elimination, control, PPE).