AP Syllabus focus:

‘Industrialization began with new technologies and access to key natural resources that powered early factories.’

Industrialization emerged as new machines and abundant natural resources transformed production, enabling societies to shift from agrarian systems toward mechanized manufacturing supported by concentrated energy sources.

Early Technological Foundations of Industrialization

The Origins of Industrialization center on the development of technologies that dramatically increased productivity. These innovations supported the shift from manual labor to mechanically powered manufacturing, laying the groundwork for major economic and spatial transformation.

The Shift to Mechanized Production

New machines fundamentally changed how goods were produced by introducing consistent, rapid, and standardized output that far exceeded traditional handcrafting. Early factories relied on these advances to scale up production.

Mechanization increased output while lowering per-unit labor requirements.

Machines encouraged standardization, making mass production possible.

Mechanized processes required centralized workspaces, contributing to the rise of modern factories.

Key technologies included the spinning jenny, power loom, and various water- and steam-powered devices that automated formerly manual tasks.

Spinning jenny in a museum setting, showing multiple spindles driven by one wheel and frame. This machine illustrates how mechanization multiplied yarn output compared with traditional hand spinning, helping to concentrate textile production in early factories. The image includes some museum display details that extend beyond the required syllabus content but remain visually secondary. Source.

Mechanization: The use of machines to replace or supplement human labor, increasing efficiency and productivity.

Mechanization concentrated production in specific locations with access to power sources, marking a major shift in industrial geography.

The Role of Energy Innovations

Energy was the backbone of early industrialization. New energy sources allowed factories to operate machinery at scales impossible with human or animal power alone.

Water wheels initially supplied energy for early mills.

Steam engines created reliable power that did not depend on physical geography.

Coal mining expanded rapidly to fuel steam technology.

Steam engines created reliable power that did not depend on physical geography.

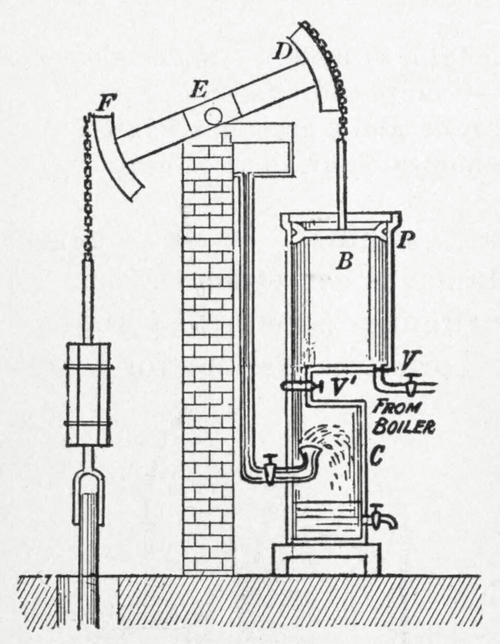

Diagram of a Watt steam engine, showing the boiler, piston, beam, and flywheel that converted steam pressure into mechanical motion. The visual helps relate the abstract concept of “steam power” to a concrete machine capable of driving factory equipment. Some technical mechanical labels extend beyond AP Human Geography requirements but support conceptual understanding. Source.

Steam Engine: A machine that converts heat energy from burning fuel into mechanical motion, enabling continuous industrial power.

Steam technology made factories more mobile, encouraging industrial expansion beyond river valleys into emerging urban centers.

Natural Resources as Drivers of Industrial Growth

Industrialization depended heavily on access to key natural resources, which determined where factories developed and how large they could grow.

Essential Raw Materials for Industrial Technologies

Industrial technologies required abundant raw materials. Areas rich in these inputs gained an early advantage.

Important resources included:

Coal, used to power steam engines and industrial furnaces

Iron ore, essential for constructing machinery, tools, and infrastructure

Water, necessary for both energy and processing in early mills

Regions with these resources—such as central England, the Ruhr Valley, and parts of New England—emerged as early industrial hubs because they could sustain large-scale production.

Raw Materials: Natural resources used in production, such as coal or iron, that are processed into finished goods.

Resource availability shaped spatial patterns of industrial development, determining where technology could be effectively applied.

Transportation Networks and Resource Accessibility

Even abundant resources required efficient transport to be useful. Expanding transportation systems enabled industries to move resources and finished goods more easily.

Key developments included:

Canals, linking inland production zones with major markets

Railroads, dramatically increasing the speed and volume of freight movement

Improved roads, enabling more consistent overland transport

These systems reduced friction of distance and expanded the geographic scale at which industrialization could operate.

Factory Systems, Efficiency, and Production Changes

Early technologies and resources supported the emergence of the factory system, a defining organizational structure of industrialization.

Centralized Production

Factories centralized labor, machinery, and energy sources into a single location to maximize efficiency.

Centralization allowed workers to specialize in particular tasks.

Supervisors and managers coordinated tasks to maintain productivity.

Production schedules kept machines running continuously, increasing output.

Factories centralized labor, machinery, and energy sources into a single location to maximize efficiency.

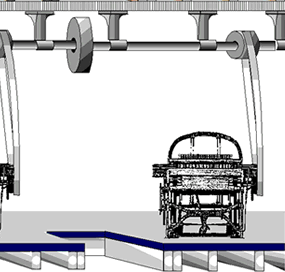

A belt-driven loom in a textile mill, showing how overhead power systems transmitted motion from water- or steam-driven shafts to individual machines. This visual demonstrates how centralized energy sources supported large-scale factory production. The photograph contains site-specific historical context beyond the syllabus, but these elements do not interfere with its instructional clarity. Source.

Factory System: A method of manufacturing using centralized workplaces where labor and machines are brought together to increase production efficiency.

This new organization represented a major departure from dispersed cottage industries, shifting economic activity toward growing industrial cities.

Spatial Implications of Early Industrial Growth

Industrial technology influenced not only production but also the spatial distribution of economic activity. New industrial centers grew around resource-rich areas and transportation corridors.

Important spatial effects included:

Concentration of industries near coalfields and waterways

Growth of towns into industrial cities with dense labor markets

Emergence of regional specialization based on resource endowments

These processes reshaped human geography by encouraging internal migration, creating industrial landscapes, and forming early manufacturing regions.

Technology–Resource Linkages and Industrial Expansion

The synergy between new technologies and critical natural resources explains why industrialization emerged where it did. Technology created demand for resources, while resource availability shaped the spread and intensity of industrial growth.

Why Technology and Resources Were Interdependent

Machines needed reliable energy sources, placing early factories near coal or water power.

Resource accessibility determined where infrastructure investments occurred.

Industrial demand stimulated further resource extraction, enabling more technological development.

These reinforcing cycles helped industrialization accelerate rapidly once initial technologies and resource networks were established.

FAQ

Scientific thinking encouraged experimentation, standard measurement, and the systematic investigation of mechanical processes, which supported improvements in early industrial machinery.

Natural philosophers and engineers increasingly collaborated, applying principles of physics to create more reliable power systems and production tools.

This scientific–engineering link helped manufacturers refine machines like looms and engines through iterative testing rather than trial-and-error craftsmanship.

Some regions benefited from established financial networks, commercial ports, and skilled craftsmen who could adopt new technologies more efficiently.

Political stability and patent laws reduced risks for workshop owners and investors.

Cultural openness to innovation also helped regions transition more quickly from small craft production to mechanised industry.

Resource extraction often produced noticeable environmental change, such as deforestation near mine sites and altered river flow near mills.

Key impacts included:

Large spoil heaps and pits from coal and iron mining

Water diversion to support mill power

Rapid settlement growth around extraction sites, transforming rural land use

Before railways, regions tested a range of transport solutions to move raw materials and finished goods more efficiently.

These included:

Horse-drawn tramways with iron rails

Canal engineering improvements such as locks and aqueducts

Early road surfacing innovations that reduced friction for heavy carts

Such experimentation smoothed the transition to railway systems once steam locomotion became viable.

Early water-powered mills depended on seasonal flow variations, which could halt production during dry periods.

Steam engines required steady coal delivery, so supply interruptions or poor transport links created downtime.

Additionally, engine maintenance was frequent, meaning factories needed on-site engineers and spare parts to maintain reliable output.

Practice Questions

Question 1 (1–3 marks)

Explain one way in which access to key natural resources contributed to the early development of industrialisation.

Mark scheme:

1 mark for identifying a relevant natural resource (e.g., coal, iron ore, water).

1 mark for explaining its role in powering or supplying early industrial technologies.

1 mark for linking the resource to increased production or the growth of early factories.

Question 2 (4–6 marks)

Analyse how technological innovation and resource availability together shaped the emergence of early industrial regions.

Mark scheme:

1–2 marks for describing at least one early technological innovation (e.g., spinning jenny, power loom, steam engine).

1–2 marks for explaining how specific natural resources supported these technologies (e.g., coal powering steam engines, water driving mills, iron ore enabling machine construction).

1–2 marks for analysing how the combination of new technologies and resource locations influenced the spatial development of early industrial centres (e.g., clustering near coalfields, river valleys, or mineral-rich areas; formation of concentrated manufacturing zones).