AP Syllabus focus:

‘Labor availability and the location of resources influence where manufacturing and other industries develop.’

Industrial location depends heavily on labor availability and proximity to key natural resources, shaping where industries emerge, expand, and maintain competitiveness in regional and global economies.

Labor as a Location Factor

Labor is one of the most influential components in determining industrial location because industries require workers with specific skills, wage levels, and productivity profiles.

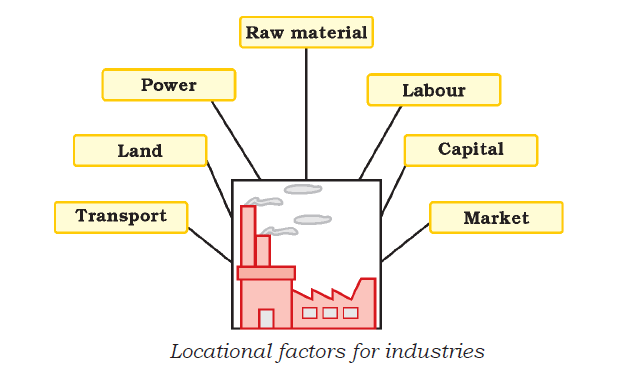

Diagram showing major locational factors for industries, including raw material and labour as core inputs that attract factories to particular places. The arrows emphasize how different inputs converge on an industrial site, illustrating why firms carefully evaluate labor availability and proximity to resources. The image also includes additional factors such as power, land, capital, transport, and market that go beyond the narrow AP syllabus focus on labor and resources. Source.

Types of Labor and Skill Levels

Industries evaluate both the quantity and quality of available labor.

Unskilled or low-skilled labor is often associated with manufacturing tasks requiring repetitive or manual work.

Skilled or specialized labor includes workers trained in advanced manufacturing, machinery operation, engineering, or technical services.

Knowledge-intensive labor, associated with research and innovation, concentrates in high-tech clusters where training institutions and talent pools are dense.

When the term labor force first appears, it refers to all people available and able to work within an economy.

Labor Force: The total number of people in a region who are employed or actively seeking employment.

Industries compare labor costs across regions and countries, leading some firms to relocate operations to areas where wages are lower or worker protections are fewer. This cost-saving strategy is a major driver behind global manufacturing shifts.

Labor Costs and Industrial Decision-Making

Labor costs vary widely across the world, and firms aim to minimize expenses without sacrificing productivity.

Regions with low labor costs are attractive for labor-intensive industries such as textiles or electronics assembly.

Regions with high labor costs tend to attract capital-intensive or high-skill industries like biotechnology or automobile engineering.

Companies also examine the stability and reliability of the workforce. This includes education levels, labor turnover, worker training availability, and the presence of labor unions that shape wage expectations and workplace regulations.

Geographic Labor Patterns

Labor availability is not evenly distributed, and industrial clusters often form near large metropolitan areas because cities supply diverse workers, training institutions, and specialized expertise. These urban labor pools reduce hiring costs and allow firms to access a wide variety of skills within a compact area.

Resources as Industrial Location Factors

The spatial distribution of natural resources plays a central role in shaping industrial patterns.

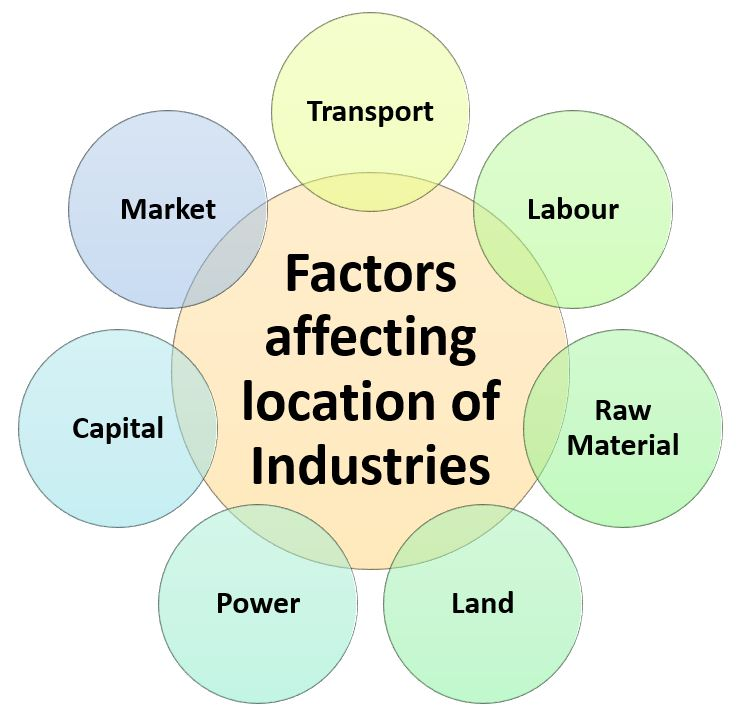

Circular diagram summarizing factors that affect the location of industries, with Labour and Raw Material shown as two of the central elements. This visual supports the idea that firms must evaluate where workers and resources are most accessible when deciding where to build factories. The diagram also includes additional factors—transport, power, land, capital, and market—which extend beyond the specific AP syllabus emphasis on labor and resources but remain commonly discussed in industrial-location analysis. Source.

Resource Proximity and Industrial Growth

Manufacturing sectors often require large quantities of bulk materials, like iron ore, coal, timber, or minerals. Locating near these resources minimizes transportation costs and promotes faster production. Heavy industries such as steelmaking or chemical production typically emerge in resource-rich regions.

For example, industries reliant on nonrenewable resources—materials that cannot replenish within human time scales—often cluster close to the extraction point. Likewise, industries using renewable resources, such as food processing or wood products, develop near agricultural regions or managed forests.

Resource-Based Manufacturing

Resource availability shapes not only where industries form but also what types of industries appear.

Extractive industries (mining, drilling, forestry) occur directly at resource sites.

Primary processing industries (smelting, refining, milling) often appear adjacent to extraction zones.

Secondary manufacturing industries rely on refined inputs and may locate farther away if transport networks make shipping efficient.

These relationships create distinct industrial belts or corridors tied to resource geographies. Over time, such regions may evolve into diversified industrial centers.

Interactions Between Labor and Resources

Labor and resources rarely operate independently as location factors. Instead, they interact to shape complex industrial landscapes.

Balancing Labor and Resource Priorities

Firms often face trade-offs between locating near resources and locating near labor supplies.

A resource-heavy industry such as steelmaking may prioritize proximity to raw materials even if labor supplies are smaller or wages are higher.

A labor-intensive industry such as apparel manufacturing may prioritize a large, low-wage workforce even if raw materials require longer transport distances.

Industries evaluate these trade-offs using least-cost principles, which compare the total expenses associated with labor, resources, and transportation. Regions that offer a combination of abundant resources and accessible labor tend to develop dense industrial clusters.

Industrial Shifts Over Time

As transportation systems improve and global trade expands, some industries become less tied to resource locations. Technological advancements allow companies to transport raw materials cheaply, enabling them to locate closer to labor markets or consumption centers instead. Conversely, some industries shift toward resource regions when extraction sites move or when environmental policies change production patterns.

Additional Influences on Labor and Resource-Based Location Decisions

While labor and resources are key factors, they operate alongside broader considerations that modify location choices.

Infrastructure quality—roads, ports, electricity—determines whether labor or resources can be efficiently utilized.

Government policies influence labor laws, resource extraction rights, and zoning regulations.

Environmental constraints affect resource availability and may limit industrial activity in ecologically sensitive areas.

These relationships demonstrate that industrial location decisions reflect a dynamic balance between human and physical geography, guided by economic priorities and constraints.

FAQ

Industries dependent on finite materials must plan for shifting extraction centres. As resources deplete, production may migrate to newly discovered reserves, altering regional industrial landscapes.

Depletion also encourages diversification. Regions once reliant on a single resource—such as coal or timber—may invest in new sectors to maintain employment and attract labour, prompting further industrial realignment.

Labour market demographics affect the age, education level, and long-term availability of workers. Younger populations attract industries needing physically demanding or repetitive labour, while highly educated populations appeal to technology-intensive sectors.

Industries also consider demographic stability; regions with declining populations may deter investment because firms anticipate future labour shortages.

Labour unions can influence wage levels, working conditions, and employer obligations. Industries that seek lower labour costs may avoid strongly unionised regions to minimise constraints.

However, some firms requiring highly skilled labour may prefer unionised areas because they offer better training, workplace stability, and predictable labour relations.

Advances in transport reduce the cost of moving materials, allowing firms to prioritise other factors such as labour availability or market access.

Industries that require specialised or large labour pools, such as electronics assembly, often accept higher transport costs in exchange for proximity to major urban centres.

Technological improvements can decrease dependency on traditional resource locations by making extraction more efficient or reducing material inputs.

Automation and synthetic substitutes may also shift industry away from resource sites. For example:

Lightweight materials reduce the need to locate near metal ores.

Renewable energy technologies allow more flexibility in power sourcing.

Practice Questions

Question 1 (1–3 marks)

Explain one way in which the availability of labour influences the location of manufacturing industries.

Mark Scheme

1 mark: Identifies a valid influence (e.g., industries locate where there is a large labour supply).

1 mark: Describes how labour characteristics matter (e.g., skills, wage levels, reliability).

1 mark: Explains the effect on industrial location (e.g., firms choose areas with lower labour costs to reduce production expenses; high-skill industries concentrate near urban centres).

Question 2 (4–6 marks)

Analyse how the distribution of natural resources and labour availability interact to shape regional patterns of industrial development.

Mark Scheme

1 mark: States that resources and labour are both key locational factors for industry.

1 mark: Explains how proximity to resources shapes initial industrial development (e.g., heavy industry near coal, iron ore, or timber).

1 mark: Explains how labour availability shapes industrial location (e.g., industries choose regions with abundant, affordable, or skilled workers).

1 mark: Analyses the interaction between labour and resources (e.g., firms make trade-offs between locating near workers or raw materials).

1 mark: Provides an example or generalised scenario showing the interaction (e.g., steel plants near resources but electronics assembly near labour).

1 mark: Shows understanding of resulting regional industrial patterns (e.g., formation of industrial belts, shift from resource-based to labour-based locations).