AP Syllabus focus:

‘Manufacturing often concentrates in core regions, while semiperiphery and periphery areas take on different roles in production networks.’

Industrial development forms uneven global patterns, with core, semiperiphery, and periphery regions each performing distinct manufacturing roles shaped by economic power, infrastructure, and global market integration.

Core, Semiperiphery, and Periphery Manufacturing Patterns

Manufacturing patterns across the world economy reflect unequal economic relationships and historical development trajectories. Understanding these patterns helps explain why some regions dominate high-value production while others specialize in lower-wage manufacturing or raw material processing. These spatial differences mirror broader global hierarchies within the world economy.

World-Systems Framework and Manufacturing

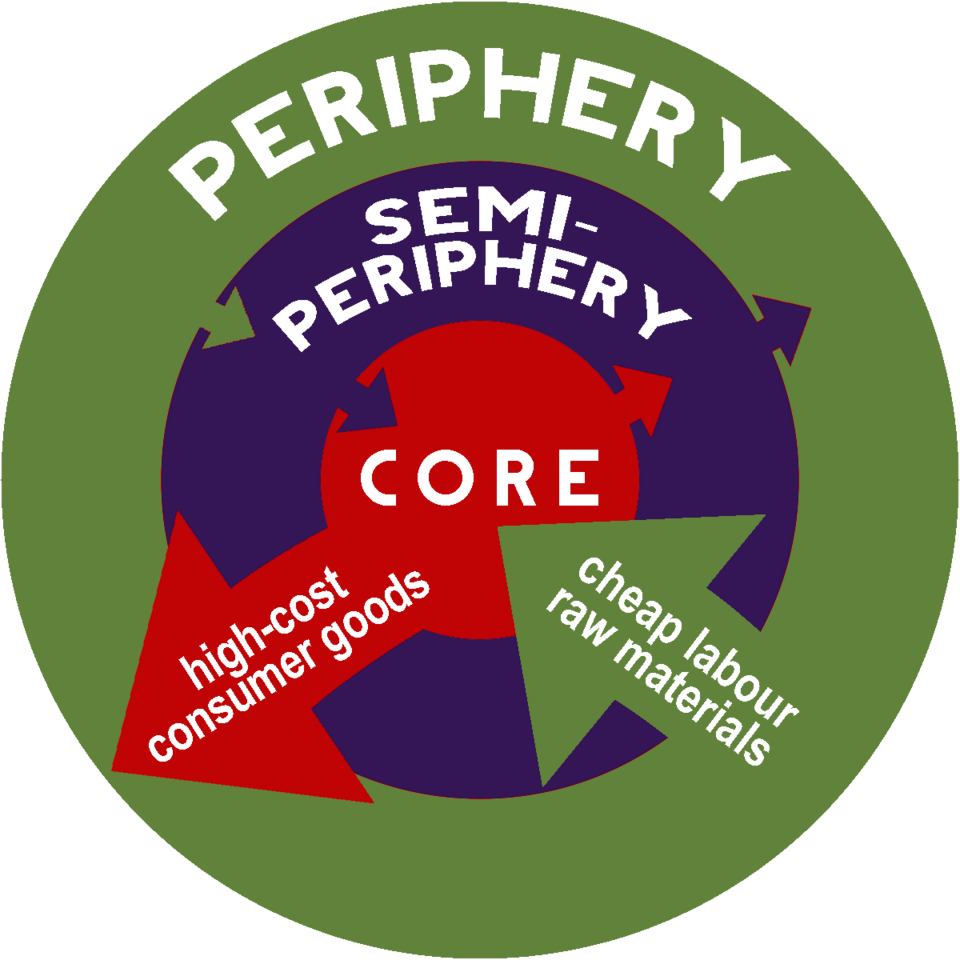

The global manufacturing landscape is often interpreted through the core–semiperiphery–periphery model, which highlights structural differences in economic power, technological capacity, and labor conditions.

Core–Semiperiphery–Periphery Model: A framework dividing the world into regions with differing economic power and industrial roles within global production networks.

Core states benefit from historic industrialization and sustained economic leadership. Semiperiphery states act as intermediaries, combining both advanced and developing economic traits. Periphery states remain less diversified, with economies tied more closely to lower-value production.

Core Manufacturing Regions

Core regions concentrate the world’s highest-value, most technologically advanced manufacturing. Their dominance reflects early industrialization, extensive capital accumulation, and strong innovation infrastructure.

Key characteristics of core manufacturing include:

High-skill, high-wage labor forces supporting advanced production.

Significant research and development (R&D) activity encouraging innovation.

Diversified industrial bases with strong tertiary and quaternary sectors.

Advanced transportation and digital networks enabling global coordination.

Examples include Western Europe, the United States, Japan, and South Korea. These areas maintain competitive advantages in aerospace, precision machinery, pharmaceuticals, and high-tech electronics. Core firms often control global supply chains, setting standards and capturing the highest share of value.

Manufacturing often concentrates in core regions, where firms benefit from skilled labor, advanced infrastructure, and large consumer markets.

A conceptual diagram of a core–periphery system shows a central core region surrounded by semiperipheral and peripheral zones. The core concentrates high-value, capital-intensive activities, while the periphery occupies lower-value positions in the global division of labor. The semi-periphery acts as an intermediate link within global production networks. Source.

Semiperiphery Manufacturing Regions

Semiperiphery states hold a hybrid position, hosting both higher-value and lower-value industries. These regions experience rapid industrial growth as they transition economically, attracting investment from both core and periphery areas.

Common features of semiperiphery manufacturing:

Expanding industrial capabilities, including mid- to high-tech manufacturing.

Improving but uneven infrastructure, especially in urban industrial corridors.

Growing domestic markets, which support consumer-goods production.

Strategic integration into global supply chains, often through export-focused zones.

Countries such as China, Mexico, Brazil, Turkey, and Malaysia host substantial manufacturing clusters, including automobile assembly, electronics, textiles, and appliances. Their competitive advantage frequently lies in moderate labor costs combined with rising technological skills. These regions often serve as global assembly centers where components from core regions are manufactured into final products.

Periphery Manufacturing Regions

Periphery regions participate in global manufacturing primarily through lower-value, labor-intensive industries or through raw material processing. Their manufacturing patterns reflect limited capital investment, weaker infrastructure, and vulnerability to global price fluctuations.

Typical traits of periphery manufacturing include:

Low-wage labor forces, often attracting cost-driven outsourcing.

Narrow industrial specialization, frequently in textiles, apparel, or resource-based processing.

Dependence on foreign firms, which control technology and capital.

Limited infrastructure, making large-scale, high-tech production difficult.

Examples include parts of Sub-Saharan Africa, South Asia, and Southeast Asia. Some periphery regions host export-processing zones (EPZs) where global firms establish factories to take advantage of low labor and regulatory costs. While such zones can generate jobs, they often reinforce dependency because value-added activities and profits flow back to core-based corporations.

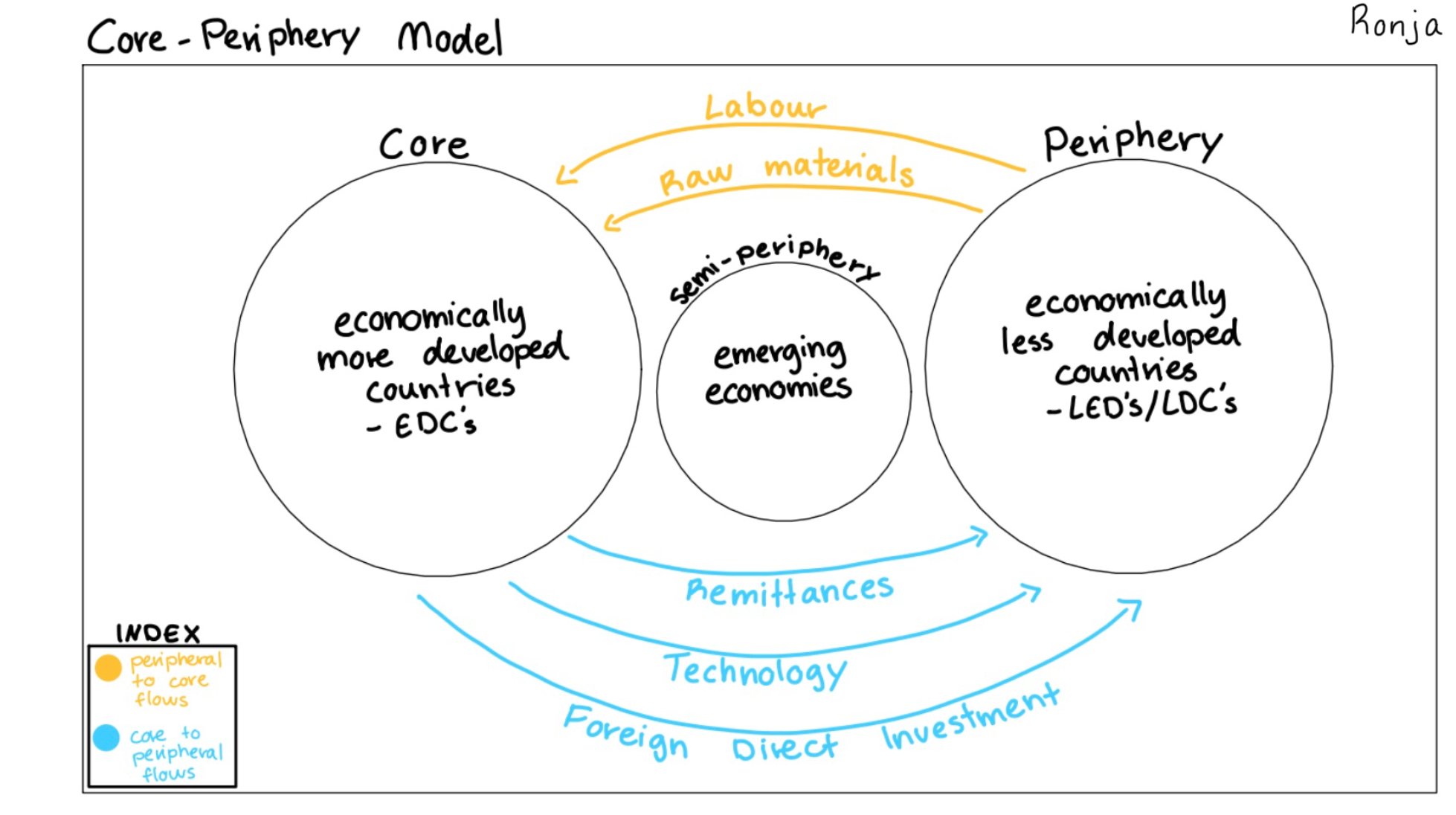

Global Production Networks and Uneven Manufacturing

Modern manufacturing relies on global production networks—international systems in which goods move through multiple countries for sourcing, assembly, and distribution. Core regions usually host corporate headquarters and advanced component production, while semiperiphery and periphery regions handle assembly and basic manufacturing.

Bullet points illustrating how regions integrate into production networks:

Core:

Design, R&D, high-tech component manufacturing

Executive decision-making and financial services

High-value branding and marketing

Semiperiphery:

Component manufacturing and product assembly

Development of domestic firms capable of competing globally

Growing technological specialization

Periphery:

Labor-intensive manufacturing or basic commodity processing

Production dependent on foreign direct investment

Limited movement into higher-value sectors

These patterns illustrate how economic power shapes industrial geographies and reinforces the centrality of core regions within the global economy.

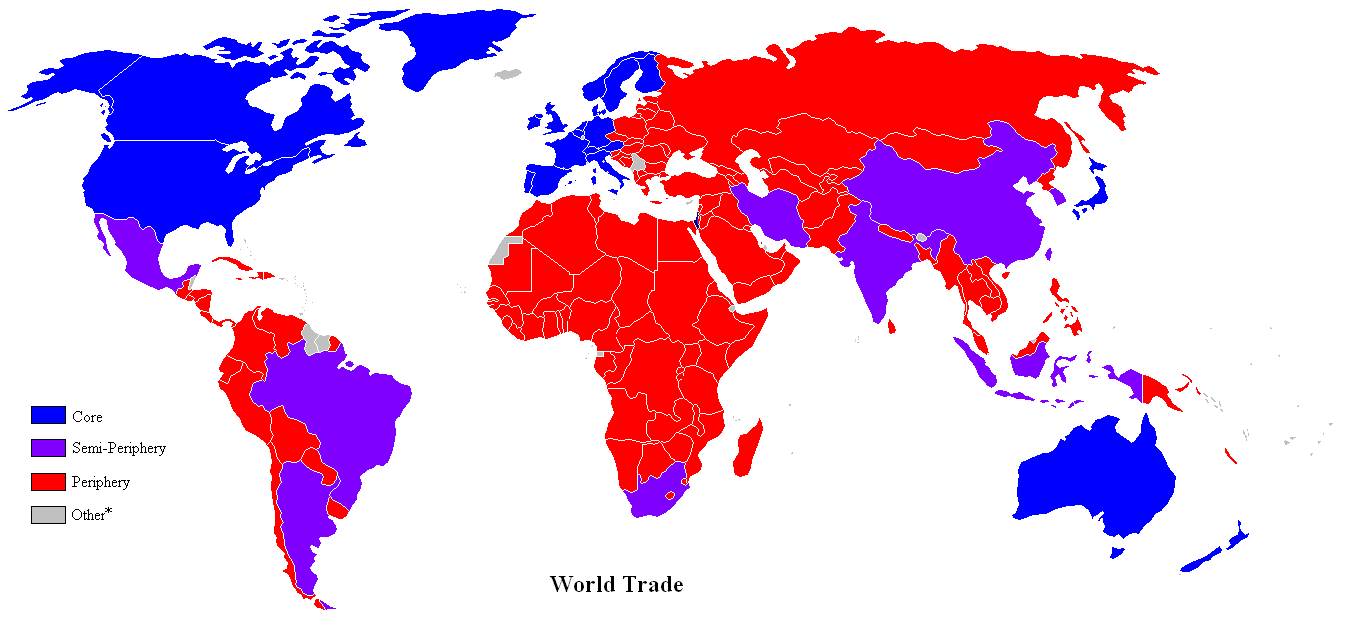

At the global scale, this creates a patterned geography of production, with clusters of high-value manufacturing in core regions, transitional belts of industry in the semiperiphery, and more limited, often resource-linked manufacturing in the periphery.

This world map classifies countries into core, semi-peripheral, and peripheral zones based on their roles in the global economy. Core regions align with high-value manufacturing and advanced services, while peripheral regions supply lower-value goods and raw materials. The model is simplified but illustrates uneven global production patterns. Source.

Spatial Shifts and Industrial Relocation

Manufacturing patterns are continually changing as firms seek lower costs, new markets, or strategic trade advantages. Relocation trends often follow predictable pathways:

From core to semiperiphery:

Firms shift assembly to reduce production costs.

Semiperiphery regions gain industrial employment and export capacity.

From semiperiphery to periphery:

Labor-intensive industries move again when wages rise.

Periphery regions absorb low-skill production while remaining dependent on foreign expertise.

These shifts demonstrate how competitive pressures and cost minimization sustain global inequalities while allowing some regions to move upward in the industrial hierarchy.

Industrial Clusters and Regional Advantages

Manufacturing often concentrates geographically, forming clusters where firms benefit from agglomeration. Core clusters dominate innovation, while semiperiphery clusters emphasize export production. Periphery clusters remain more limited in scale and diversity.

Clusters reflect:

Shared infrastructure

Skilled labor pools

Supplier networks

Transportation access

Their development reinforces existing core–semiperiphery–periphery structures, strengthening the overall unevenness of global industrialization.

Semiperipheral and peripheral regions are linked to the core through flows of raw materials, intermediate goods, investment, and labor, forming global production networks that knit together different stages of manufacturing.

This diagram illustrates flows between core, semiperipheral, and peripheral regions, including goods, capital, and labor. It highlights how core economies dominate high-value production while relying on lower-value manufacturing and resource extraction elsewhere. Some elements, such as remittances, extend beyond the AP syllabus but help contextualize global production networks. Source.

FAQ

Historical trade routes helped early industrial powers consolidate wealth, infrastructure, and global connections. These advantages created long-term path dependency, reinforcing which regions would become today’s core.

Peripheral regions that were historically controlled, colonised, or integrated as suppliers of raw materials often developed weaker industrial bases, shaping their present-day manufacturing roles.

Semiperipheral regions frequently emerged where historical trading crossroads or colonial port cities facilitated early industrial growth and foreign investment.

Several structural barriers limit upward mobility:

Limited capital investment

Weak transport and energy infrastructure

Dependence on foreign-owned firms

Vulnerability to global price fluctuations

These constraints reduce the ability of peripheral economies to diversify beyond low-wage, labour-intensive production, making the transition to more technologically advanced manufacturing difficult.

Semiperipheral regions often offer a blend of moderate labour costs, improving infrastructure, and growing consumer markets.

They also tend to have governments willing to create export-oriented industrial zones, invest in education, and encourage foreign direct investment.

This mixed economic environment allows them to host both advanced assembly operations and lower-value industries shifting out of the core.

Multinational corporations shape production by locating high-value design and management functions in core regions while outsourcing assembly or components to semiperipheral and peripheral areas.

They often control supply chains, technology transfer, and profit distribution, reinforcing unequal patterns of value capture.

Peripheral regions may become dependent on multinational activity, while semiperipheral regions can leverage it to strengthen domestic industries.

Connectivity alone does not eliminate differences in economic power, technology, or political stability.

Core regions continue to dominate innovation and high-value sectors, while many semiperipheral and peripheral regions face structural constraints such as weaker institutions or volatile markets.

Even with global supply chains, most value-added activities remain concentrated in the core, maintaining the hierarchical pattern.

Practice Questions

Question 2 (4–6 marks)

Using the core–semiperiphery–periphery model, outline how manufacturing roles differ between these three global regions.

Mark scheme:

• 1 mark for accurately describing the manufacturing role of core regions (e.g., high-tech, high-value production).

• 1 mark for accurately describing the manufacturing role of semiperipheral regions (e.g., mixed mid- to high-level manufacturing, global assembly).

• 1 mark for accurately describing the manufacturing role of peripheral regions (e.g., low-wage, labour-intensive production or raw material processing).

• 1 mark for explaining how these roles are linked through global production networks.

• Up to 2 additional marks for depth, clarity, and accurate use of geographic terminology (e.g., value-added, foreign direct investment, supply chains).

Question 1 (1–3 marks)

Explain one reason why manufacturing is more likely to be concentrated in core regions than in peripheral regions.

Mark scheme:

• 1 mark for identifying a valid reason (e.g., access to skilled labour, advanced infrastructure, capital availability).

• 1 mark for explaining how this reason supports manufacturing concentration.

• 1 mark for linking the explanation to characteristics of core regions (e.g., technological advantages, market access).