AP Syllabus focus:

‘Least-cost ideas explain how firms choose locations that minimize production and transportation costs while still reaching markets.’

Industrial location decisions rely on least-cost thinking, a core geographic principle explaining how firms select sites that reduce expenses while maintaining access to consumers. Firms balance transportation, labor, and agglomeration factors to produce goods efficiently and competitively.

Least-Cost Thinking in Industrial Geography

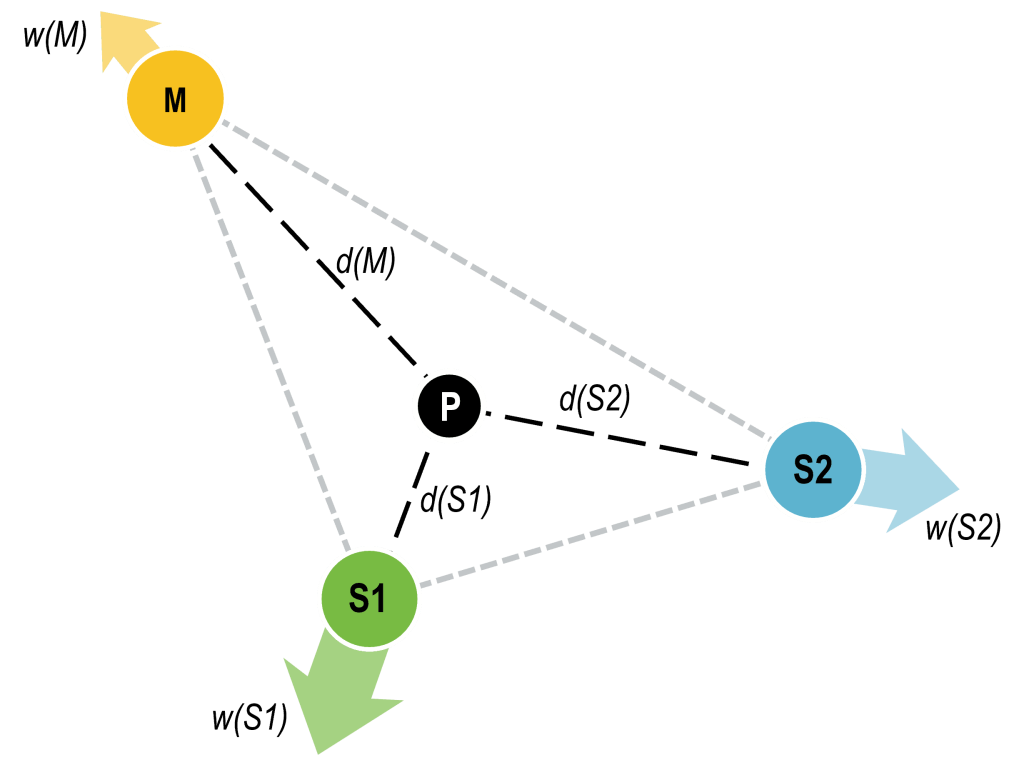

Least-cost thinking is rooted in the idea that manufacturers seek locations where total production expenses are minimized without sacrificing the ability to reach markets. This approach shapes spatial patterns of industrial development by directing firms toward sites with cost advantages. The best-known framework for this process is Alfred Weber’s Least Cost Theory, which highlights transportation costs, labor costs, and agglomeration effects as the primary forces behind industrial location choices. Weber’s least-cost theory visualizes this decision with a locational triangle linking raw-material sites, the market, and a potential factory site that minimizes overall transport costs.

This diagram illustrates Alfred Weber’s locational triangle, where a factory site P is selected to minimize the transportation cost between raw material sources and the market. The dashed lines represent transport links, and the arrows indicate flows of materials and finished goods. The image focuses solely on transportation cost minimization and does not depict later adjustments for labor or agglomeration. Source.

Core Cost Factors in Manufacturing Location

Three broad cost categories influence firm decision-making: transportation, labor, and agglomeration. These factors push and pull firms toward specific regions, creating clusters, corridors, and shifting industrial landscapes.

Transportation Costs: The expenses associated with moving raw materials to factories and finished goods to markets.

Transportation is often the most important factor because distance and weight directly influence cost. Firms producing goods with heavy raw materials and lighter finished products may locate near resource sources, while firms whose products gain weight during production may locate closer to markets.

Industrialists also assess available transportation networks such as highways, rail lines, ports, and airports. Improved intermodal systems—especially containerization—lower costs by simplifying movement between modes.

Labor Costs: The expenses incurred from employing workers, including wages, benefits, and necessary skill levels.

Labor considerations affect location when high wages raise operating costs or when skilled workers cluster in particular regions. Firms requiring inexpensive, abundant labor may gravitate to developing countries or right-to-work states, while high-tech industries concentrate in skilled labor hubs.

A normal sentence fits here to provide continuity between the concepts.

Agglomeration: The clustering of firms and services in a shared location to benefit from reduced costs, shared labor pools, and specialized suppliers.

Agglomeration can reduce expenses by creating economies of scale. When firms cluster, they can share suppliers, infrastructure, and knowledge, enhancing innovation and productivity. However, excessive clustering may lead to agglomeration diseconomies, such as congestion, higher rents, and rising wages.

Transportation and Market Access

Market access is essential because firms must deliver goods to consumers efficiently. Least-cost thinking emphasizes balancing proximity to raw materials with proximity to markets. The chosen location depends on which side offers the largest reduction in transportation expenses.

Material Index and Locational Decisions

Weber introduced the concept that industries with high raw material weight loss during production (such as lumber or copper processing) tend to locate near resources. In contrast, industries whose raw materials do not lose weight often locate closer to consumers, reducing final delivery costs.

Industries also weigh the availability of multimodal transport corridors. Regions with ports, rail terminals, and highways often attract manufacturing because they reduce friction of distance.

Labor Considerations and Regional Patterns

Labor availability interacts with transportation factors. Sometimes cheap labor savings outweigh higher transportation costs, pulling firms away from traditional cores into peripheral or semiperipheral regions.

Outsourcing and Footloose Industries

Some industries, known as footloose industries, can locate almost anywhere because transportation costs are negligible. These firms focus on labor cost savings or access to skilled professionals. Information technology, electronics assembly, and service-based manufacturing exemplify this pattern.

Agglomeration Benefits and Industrial Clustering

Agglomeration explains why some industries group in particular cities or regions, forming specialized zones. Clusters such as Silicon Valley or the Research Triangle emerge because firms benefit from shared labor markets, research institutions, and supplier networks.

Economies of Scale in Industrial Centers

When firms cluster, they often achieve economies of scale, lowering average costs as production volume increases. Firms located within clusters can access cheaper inputs, attract skilled labor, and innovate more rapidly. Clustering also stimulates complementary industries, expanding regional economic ecosystems.

A normal sentence here ensures clear separation between definition blocks.

Economies of Scale: Cost advantages that result when production becomes more efficient as output increases.

Industrial parks and export-processing zones demonstrate agglomeration, where many firms cluster in planned estates near major transport routes to share infrastructure, labor pools, and service networks.

The aerial view shows a planned industrial area composed of warehouses and factory buildings arranged along wide internal roads. This spatial pattern demonstrates how firms cluster to benefit from shared infrastructure, strong transport access, and appropriately zoned industrial land. The image does not label specific firms or cost factors but clearly represents an agglomerated manufacturing zone. Source.

Least-Cost Thinking and Global Manufacturing Patterns

Globalization has intensified least-cost strategies. Firms now compare international labor markets, transportation corridors, and trade policies. This has encouraged manufacturing migration from traditional industrial cores to newly industrialized economies where labor is cheaper and regulations may be more flexible.

Balancing Cost Minimization with Market Reach

Despite the pursuit of low costs, firms must still reach consumers. Therefore, manufacturers blend least-cost logic with considerations such as trade agreements, tariffs, and shipping times. Regions offering a combination of low production costs and good market access—such as Mexico’s border zones or Southeast Asian export hubs—have become major manufacturing centers.

Least-cost thinking ultimately produces dynamic and evolving industrial geographies as firms continuously adjust location strategies to minimize expenses while maintaining competitiveness.

FAQ

Footloose industries demonstrate what happens when transportation costs are so low or inputs so lightweight that location decisions rely mainly on labour, infrastructure quality, or tax incentives.

These firms can situate themselves in a wide range of regions because their operating expenses are not heavily tied to proximity to raw materials or markets, making their least-cost strategies far more flexible.

Some industries rely on specialised skills, advanced technical expertise, or a highly educated workforce, which cannot be easily replicated in low-cost areas.

Firms may also prioritise:

• High-quality infrastructure

• Stable regulatory environments

• Reliable suppliers and logistics networks

All of these can outweigh the benefits of lower wages in alternative locations.

Governments can shift cost structures by offering tax incentives, subsidies, or reduced land prices within designated industrial zones, making certain locations more appealing.

They also develop infrastructure—ports, highways, and utilities—that effectively reduces transport and operational costs for firms applying least-cost reasoning.

Global supply chains create opportunities for firms to place each production stage in a region where a specific cost is minimised, such as labour, shipping, or components.

This results in:

• Multi-country production networks

• Reduced unit costs through specialisation

• Increased reliance on efficient transport corridors

Least-cost thinking becomes a multi-step calculation rather than a single-site decision.

Environmental rules can raise production costs by requiring cleaner technologies, waste treatment, or pollution controls, making heavily regulated areas more expensive to operate in.

As a result, firms may choose sites with:

• Less stringent regulations

• Lower compliance costs

• More flexible planning requirements

These choices are weighed alongside transport, labour, and agglomeration factors in determining the lowest overall cost location.

Practice Questions

Question 1 (1–3 marks)

Explain one way in which transportation costs influence the location of manufacturing.

Question 1

1 mark:

• Identifies a basic link between transport costs and industrial location (e.g., firms prefer sites with lower transport costs).

2 marks:

• Provides a clear explanation of how transportation costs affect location (e.g., firms choose locations closer to raw materials or markets to reduce freight expenses).

3 marks:

• Provides a detailed explanation with specific reasoning (e.g., weight-loss industries locate near raw materials to minimise the cost of moving heavy inputs; market-oriented industries move closer to consumers to reduce delivery costs).

Question 2 (4–6 marks)

Using the concept of least-cost thinking, explain how transportation, labour, and agglomeration factors interact to shape the location of manufacturing industries. Refer to Weber’s ideas in your answer.

Question 2

4 marks:

• Identifies all three factors (transportation, labour, agglomeration).

• Provides a basic explanation of each factor’s role in least-cost location.

5 marks:

• Shows interaction between factors (e.g., labour savings may offset higher transport costs; agglomeration can reduce operational costs and attract related industries).

• Mentions Weber’s least-cost theory or the locational triangle.

6 marks:

• Gives a well-developed and coherent explanation showing how firms balance these factors simultaneously.

• Includes clear reference to Weber’s argument that firms minimise total costs through the optimal combination of transportation, labour, and agglomeration.

• May describe how different industries prioritise these factors differently (e.g., labour-intensive vs. transport-oriented industries).