OCR Specification focus:

‘Suggest realistic improvements to procedures and apparatus to refine experimental design and enhance data quality.’

Improving procedures and apparatus in physics experiments is vital for achieving reliable, valid, and precise data. Refinement enhances experimental design, reduces uncertainty, and strengthens confidence in conclusions.

Understanding the Purpose of Improvement

Scientific experiments rarely achieve perfection on the first attempt. Recognising weaknesses in procedure or apparatus allows for refinement that directly improves data quality and the validity of conclusions. In OCR A-Level Physics, this skill reflects a student’s ability to think critically about how data is collected and how scientific methods can be optimised.

Key Aims of Improvement

Enhance accuracy and precision of measurements.

Reduce systematic and random errors.

Increase reproducibility across multiple trials.

Ensure safety and feasibility in the practical setup.

Strengthen validity, ensuring results genuinely test the intended hypothesis.

Refining Experimental Procedures

Procedures describe the step-by-step method followed during an investigation. To improve them, physicists must identify potential weaknesses that could reduce reliability or introduce bias.

Sources of Procedural Limitations

Human error in timing, reading instruments, or aligning equipment.

Inadequate control of environmental factors such as temperature, light, or air currents.

Inconsistent measurement techniques, such as different observers recording readings differently.

Insufficient number of repeats, reducing statistical confidence in results.

Unclear procedural steps, leading to variation between experimenters.

Strategies to Improve Procedures

Increase Repetition – Repeating measurements reduces the impact of random errors and allows for more accurate mean values.

Standardise Methodology – Clearly defined procedures ensure all experimenters follow the same steps, improving reproducibility.

Control Variables More Rigorously – Use controlled environments or digital sensors to maintain constant conditions.

Automate Data Collection – Replace manual timing or reading with data loggers or motion sensors to eliminate human error.

Extend Range of Data – Taking a wider range of readings can reveal trends and identify anomalies more effectively.

Improve Calibration Routines – Regularly calibrating instruments ensures they provide accurate readings throughout the experiment.

Enhancing Apparatus Design

Apparatus quality directly affects the precision and reliability of data. Poorly designed or imprecise equipment can introduce systematic errors, which consistently skew results in one direction.

Common Apparatus Issues

Low-resolution instruments, limiting measurable accuracy.

Misaligned components, such as optical setups not perpendicular to surfaces.

Poorly calibrated sensors, producing consistently offset results.

Inappropriate equipment choice, such as using a metre rule instead of a micrometer for fine measurements.

Methods for Apparatus Improvement

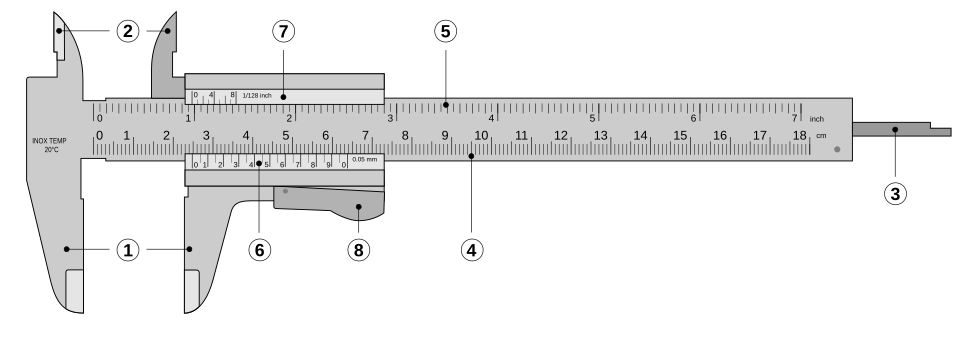

Increase instrument sensitivity – Select equipment with finer scales or higher resolution (e.g., digital vernier calipers).

A Vernier caliper with labelled main scale and vernier scale, used for precise internal, external, and depth measurements. Its fine resolution reduces absolute and percentage uncertainty compared with a metre rule. Using higher-resolution apparatus is a realistic improvement to refine data quality. Source.

Improve stability – Use clamps and stands to reduce vibration or movement affecting readings.

Ensure proper alignment – Optical and mechanical setups must be precisely aligned to eliminate parallax or angular errors.

Upgrade measurement technology – Utilise digital or electronic devices where possible to enhance precision and consistency.

Use calibration standards – Compare instruments against known reference values before and after use to identify drift.

Managing and Reducing Errors

Random Errors

Caused by unpredictable fluctuations in measurement, such as reaction time or environmental changes.

To minimise them:

Repeat readings and calculate mean values.

Use instruments with smaller scale divisions.

Employ consistent observation techniques.

Systematic Errors

These occur due to consistent faults in apparatus or method.

To address them:

Identify and correct for zero errors in instruments.

Replace or recalibrate faulty equipment.

Compare results against known standards to detect bias.

Uncertainty: The estimated range within which the true value of a measured quantity lies, based on instrument precision and method reliability.

Reducing uncertainty through apparatus improvement ensures higher confidence in measured data and strengthens the validity of conclusions.

Data Quality and Reliability

Data quality reflects how dependable the measurements are for supporting valid conclusions. Reliability is improved when data are consistent across multiple trials or different setups.

Ways to enhance data quality include:

Reducing measurement uncertainty by using higher-precision instruments.

Improving experimental design to eliminate unnecessary sources of variation.

Cross-checking data with theoretical predictions or alternative methods.

Implementing error analysis to identify dominant sources of uncertainty and target improvements effectively.

EQUATION

—-----------------------------------------------------------------

Percentage Uncertainty (%) = (Absolute Uncertainty ÷ Measured Value) × 100

Absolute Uncertainty = Half of the smallest scale division or the estimated reading uncertainty

Measured Value = Recorded experimental value in relevant SI units

—-----------------------------------------------------------------

This equation helps evaluate whether apparatus improvements successfully reduce uncertainty levels and therefore increase precision.

Systematic Approach to Refinement

Step 1: Identify Weaknesses

Analyse previous data and experimental notes to locate points where accuracy or precision was compromised.

Step 2: Diagnose Causes

Determine whether errors arose from procedural inconsistencies, apparatus faults, or uncontrolled variables.

Step 3: Propose Targeted Changes

For each weakness, suggest specific modifications—such as replacing equipment, revising instructions, or adjusting measurement intervals.

Step 4: Re-Test and Validate

Repeat the experiment with the proposed improvements, compare new data to original results, and assess if the data quality and consistency have improved.

Step 5: Document and Reflect

Maintain detailed records of all modifications and outcomes. Reflection supports future investigations and aligns with good scientific practice.

Examples of Effective Improvements

Using light gates instead of a stopwatch in motion experiments to remove human reaction time error.

Replacing analogue thermometers with digital thermocouples for finer temperature resolution.

A metal-sheathed thermocouple probe converts a temperature difference at its junction into a voltage, read by a meter or data logger. Digital temperature sensing improves resolution and enables automated logging, reducing parallax and interpolation errors. Some thermocouple variants shown on Commons include industrial probe designs beyond typical school labs; the essential sensing principle is the same. Source.

Conducting measurements in a draught-free enclosure during heat loss experiments to control convection effects.

Employing longer measuring instruments for pendulum experiments to reduce fractional uncertainty in length.

Using data logging software for automated collection and real-time graphical analysis.

These enhancements improve both accuracy (closeness to the true value) and precision (consistency of repeated measurements), ultimately refining the experimental design in accordance with the OCR specification requirement.

FAQ

Improving accuracy means reducing systematic errors so results are closer to the true value, for example by calibrating instruments correctly or removing zero errors.

Improving precision focuses on reducing random errors and making repeated measurements more consistent, such as by taking multiple readings and averaging them.

A high-precision result can still be inaccurate if the apparatus has a systematic bias, so both accuracy and precision must be addressed to improve overall data quality.

Data loggers automatically record readings such as temperature, voltage, or time without human intervention. This reduces reaction-time and reading errors.

They also enhance safety by allowing measurements to be taken remotely during experiments involving heat, chemicals, or high voltages.

Additionally, continuous recording provides more data points for analysis, allowing clearer trend identification and improved reliability in interpreting results.

Calibration ensures that instruments provide readings that correspond accurately to known standards. Even precise instruments can drift over time due to wear, temperature changes, or electrical instability.

Regular calibration:

Removes consistent offset errors.

Verifies the linearity of sensor response.

Maintains comparability between different instruments used in the same investigation.

Without calibration, small systematic errors may go unnoticed, reducing confidence in the data’s validity.

Students may face resource and cost limitations, as advanced equipment like digital sensors or data loggers can be expensive.

Practical space constraints, limited time, and safety rules can also restrict modifications such as using long measuring ranges or heavy apparatus.

In such cases, improvements often focus on low-cost refinements, including:

Better alignment of equipment.

More consistent control of environmental factors.

Increasing repeats to strengthen data reliability.

Even with refined apparatus, uncontrolled environmental variables can undermine improvements. For example:

Temperature changes can affect metal expansion, influencing length or resistance measurements.

Air currents can alter readings in pendulum or heat experiments.

Vibration or background noise can interfere with sensitive sensors.

To maintain the benefit of apparatus upgrades, conditions should be stabilised or monitored carefully—using draught shields, thermostatic control, or vibration damping where appropriate.

Practice Questions

Question 1 (2 marks)

A student measures the diameter of a wire using a digital micrometer that reads to 0.001 mm. Suggest one improvement to the student’s procedure and explain how it would improve the reliability of the data.

Mark scheme:

1 mark for suggesting an appropriate improvement, such as:

Taking multiple measurements along the length of the wire and calculating a mean value.

Ensuring the micrometer is zeroed before use.

1 mark for explaining the improvement’s effect on data reliability, such as:

Averaging readings reduces random errors and improves consistency.

Zeroing removes systematic error, improving accuracy of all measurements.

Question 2 (5 marks)

An experiment is conducted to investigate how the extension of a spring varies with applied force. The student measures force using slotted masses and extension with a metre rule. The plotted results show a linear relationship, but the scatter of points is larger than expected.

(a) Identify two potential sources of error in the student’s method. (2 marks)

(b) Suggest two realistic improvements to the apparatus or procedure that would enhance data quality, and explain how each improvement would reduce uncertainty or error. (3 marks)

Mark scheme:

(a) (2 marks – 1 mark each)

Parallax error when reading the metre rule.

Non-uniform spring or measurement of extension from an inconsistent reference point.

Friction in the spring support or clamps affecting motion.

(b) (3 marks – 1 mark per improvement, 1 mark per explanation up to 3 total)

Use a vertical retort stand with a pointer attached to the spring to reduce parallax error → ensures consistent eye level reading (1).

Replace the metre rule with a digital position sensor or motion sensor → increases measurement precision and eliminates reading bias (1).

Use slotted masses of smaller increments → allows a finer range of data points, improving accuracy and identifying anomalies (1).

Ensure the spring is calibrated or pre-loaded before measurement → removes slack and reduces systematic error (1).

(Max 3 marks for part b)