OCR Specification focus:

‘Explain the piezoelectric effect and how transducers emit and receive ultrasound.’

Piezoelectric transducers are essential devices in medical ultrasound, enabling both the generation and detection of high-frequency sound waves through the distinctive behaviour of piezoelectric materials under electrical influence.

Piezoelectric Transducers

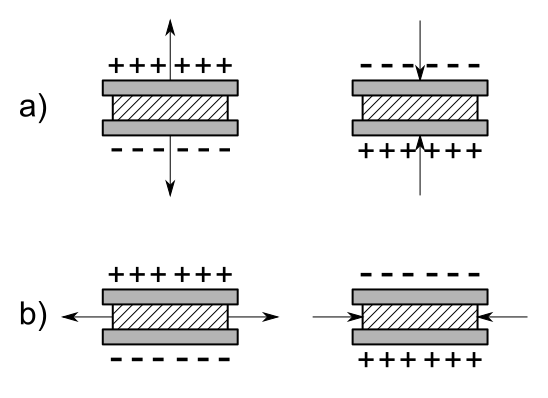

Piezoelectric transducers form the core of most medical ultrasound systems. They rely on the piezoelectric effect, which links mechanical deformation of certain crystals to the production of electric charge, and the reverse process in which an applied electric field causes the crystal to change shape. This dual capability allows the same component to act as both a source and detector of ultrasound.

Piezoelectric effect: The property of specific materials to generate electric charge when mechanically deformed, and conversely to deform when an electric field is applied.

In medical imaging, transducers must generate ultrasound frequencies typically in the range of several megahertz.

Diagram showing how mechanical deformation of a crystal generates charge separation through the piezoelectric effect. The axes and crystallographic detail extend beyond syllabus requirements but reinforce the underlying physical principle. Source.

Structure of a Piezoelectric Transducer

The main functional element is a piezoelectric crystal, usually lead zirconate titanate (PZT), selected for its strong response, durability, and ability to vibrate at a stable resonant frequency. The crystal is positioned between two electrodes that supply the alternating potential difference needed for controlled oscillation.

Key components

Piezoelectric crystal (PZT): Vibrates rapidly when an alternating voltage is applied, producing longitudinal pressure waves.

Electrodes: Provide contact for the electrical driving signal and allow detection of returned echoes.

Backing material: A dense, acoustically absorbing layer behind the crystal that damps unwanted vibrations, improving resolution and signal clarity.

Matching layer: A material placed in front of the crystal to reduce the mismatch in acoustic impedance between the PZT and human tissue, increasing transmission efficiency.

Protective housing: Ensures sterility and provides structural support for clinical use.

Image showing the internal structure of a real ultrasound transducer, including piezoelectric elements, wiring, and support materials. Additional engineering detail beyond syllabus requirements provides valuable real-world context. Source.

Between these components, energy transfer must be optimised to produce ultrasound pulses of the necessary intensity while avoiding excess ringing that would reduce image sharpness.

Generating Ultrasound

To emit ultrasound, the transducer is supplied with an oscillating electrical signal at the resonant frequency of the crystal.

Process of emission

An alternating potential difference is applied across the electrodes.

The crystal alternately expands and contracts due to the inverse piezoelectric effect.

These rapid vibrations create longitudinal pressure waves in the attached matching layer.

The waves then enter the patient’s body, travelling through tissues until they encounter boundaries and reflections occur.

The amplitude and duration of the electrical pulse determine the intensity and shape of the ultrasound wave. Since medical ultrasound commonly requires short pulses, damping by the backing material is essential to prevent prolonged oscillations.

Receiving Ultrasound

After emission, the same crystal switches role to act as a receiver. When returning echoes strike the crystal, they induce minute mechanical deformations.

Detection mechanism

Incident ultrasound waves compress and stretch the crystal.

These mechanical changes generate an electrical signal across the electrodes through the direct piezoelectric effect.

The resulting signal is extremely small and requires amplification.

The amplified signal is then processed to determine echo timing and intensity, forming the basis of the displayed image.

A single transducer element may both emit and receive, or an array of elements may work together to allow beam steering and focusing in more advanced imaging systems.

Resonance and Frequency Selection

The operational frequency of a transducer depends primarily on the crystal’s thickness and material properties. Thinner crystals resonate at higher frequencies, producing ultrasound suited to superficial imaging, while thicker crystals generate lower frequencies capable of penetrating deeper tissues.

EQUATION

—-----------------------------------------------------------------

Resonant Frequency (f) = c / (2t)

f = Resonant frequency of the crystal (Hz)

c = Speed of sound in the crystal material (m s⁻¹)

t = Thickness of the crystal (m)

—-----------------------------------------------------------------

This relationship illustrates why precise manufacture is necessary. Even small variations in thickness alter the resonant frequency significantly, influencing the quality of the resulting image.

A wide bandwidth is also desirable for short-duration pulses used in pulse-echo methods. The backing material and matching layers help shape this bandwidth by controlling how the crystal stores and releases energy.

Acoustic Coupling and Practical Considerations

For efficient operation, ultrasound must pass easily from the transducer into the body.

Photograph of a clinical ultrasound probe, showing the handheld transducer head that houses the piezoelectric elements. Although internal components are not visible, this image links theoretical descriptions to the device used in medical imaging. Source.

Clinical design considerations

Durability: Transducers must withstand frequent sterilisation and mechanical handling.

Safety: Output intensities must remain within established medical limits.

Signal fidelity: High-quality backing and matching materials ensure clear pulse transmission and reception.

Temperature stability: Crystal properties must remain reliable despite heating during operation.

Modern transducers may include arrays of many small crystals, electronic control circuits, and protective layers, but all depend on the fundamental piezoelectric effect described above.

FAQ

Manufacturers control resonance mainly by adjusting the thickness of the piezoelectric crystal, since the resonant frequency is inversely proportional to thickness.

Small-scale machining techniques, such as precision lapping and polishing, are used to achieve tolerances within micrometres.

Additional fine-tuning may be achieved by altering electrode mass or adding thin matching layers that slightly shift the vibrational characteristics.

PZT produces a much stronger piezoelectric response than quartz, allowing efficient generation of high-frequency ultrasound needed for medical imaging.

It can also be chemically modified to tailor properties such as Curie temperature, electromechanical coupling, and stability.

Quartz is mechanically stable but provides weaker signals, making it unsuitable for compact, high-performance probes.

Bandwidth is determined by how quickly the crystal stops vibrating after each pulse. This depends on:

• the strength of damping from the backing material

• the material properties of the crystal

• the thickness and design of matching layers

A wider bandwidth allows shorter pulses, which improves axial resolution and makes fine structural details easier to distinguish in medical imaging.

A single matching layer cannot fully bridge the acoustic impedance gap between PZT and soft tissue.

Multiple thin layers, each with an intermediate impedance, reduce reflections more effectively and improve energy transmission.

This design increases emitted intensity while also strengthening returning echoes, enhancing overall image quality.

Limitations arise from both equipment safety and biological safety.

Equipment constraints include overheating of the crystal, depolarisation if temperatures approach the Curie point, and electrical breakdown of electrodes.

Biological limits are defined by regulations that restrict thermal and mechanical effects in tissue, ensuring ultrasound does not cause heating or cavitation at clinical intensities.

Practice Questions

Question 1 (2 marks)

State what is meant by the piezoelectric effect and explain how it allows a crystal to act as an ultrasound emitter.

Question 1 (2 marks)

1 mark: States that the piezoelectric effect is the production of electric charge when a crystal is deformed, or that the crystal changes shape when a voltage is applied.

1 mark: Explains that applying an alternating voltage makes the crystal vibrate, producing ultrasound waves.

Question 2 (5 marks)

An ultrasound transducer contains a thin slab of piezoelectric material connected to an alternating potential difference.

Describe in detail how the transducer generates and then detects ultrasound waves. In your answer, you should refer to:

• the behaviour of the crystal when the alternating voltage is applied

• the role of resonance

• how returning ultrasound waves produce an electrical signal

• any components that help ensure clear pulse emission and reception.

Question 2 (5 marks)

Award marks for any five of the following, up to a maximum of 5:

Alternating potential difference causes the crystal to expand and contract (inverse piezoelectric effect).

These rapid oscillations create longitudinal pressure waves (ultrasound).

Crystal vibrates at its resonant frequency, determined by its thickness and material.

Returning ultrasound compresses and stretches the crystal (direct piezoelectric effect).

This generates a small alternating electrical signal proportional to the incident wave.

Backing material reduces ringing and produces short pulses for clearer imaging.

Matching layer improves transmission by reducing acoustic impedance mismatch.