OCR Specification focus:

‘Identify X-ray tube components: heater (cathode), anode, target metal, and high-voltage supply.’

X-ray Tube Structure

A modern medical X-ray tube is a controlled device designed to generate high-energy X-ray photons for diagnostic imaging by accelerating electrons and making them interact with a metal target.

Overview of the X-ray Tube Assembly

The X-ray tube is a sealed, evacuated glass or metal envelope containing the essential components required to produce X-rays safely and efficiently.

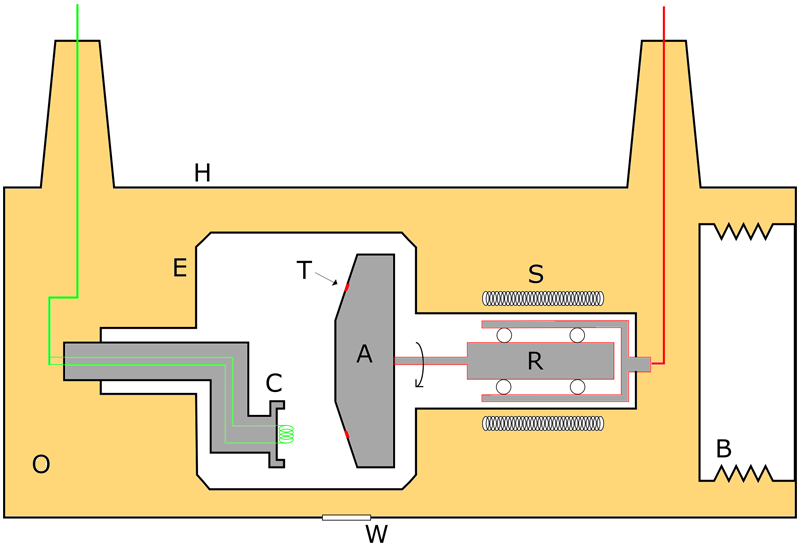

A schematic showing the cathode with heating coil, the anode and angled target, the evacuated tube envelope and window, and additional housing features such as cooling oil that extend beyond the OCR requirement but support understanding of how the tube is supported and cooled. Source.

Inside the evacuated environment, electrons travel unimpeded from one electrode to another, ensuring efficient production of radiation. The structure also incorporates elements for heat removal, electrical insulation, and stable mechanical support.

The Cathode and Heater

The cathode is the negatively charged electrode responsible for releasing electrons through thermionic emission. This occurs when a small internal heating element, known as the heater, raises the temperature of the cathode to the point at which electrons gain enough energy to escape from the metal surface.

Thermionic Emission: The release of electrons from a heated metal surface due to increased thermal energy.

After electrons are emitted, they are focused into a narrow beam by a focusing cup surrounding the heated element. These electrons then accelerate towards the positively charged anode due to the applied high-voltage potential difference.

The heater requires only a low voltage to operate, but its stable performance is essential because the rate at which electrons are emitted directly influences both the X-ray beam intensity and the thermal load placed on the target assembly.

The Anode Assembly

The anode is the positively charged electrode designed to attract and rapidly decelerate the incoming electrons. It typically rotates in most diagnostic X-ray tubes, although simple fixed-anode systems exist for lower-intensity applications.

As electrons collide with the anode, their kinetic energy is converted into X-ray photons and heat. The anode structure is engineered to withstand extremely high temperatures, because more than 99% of the kinetic energy transferred to the target becomes heat instead of useful radiation.

The Target Metal

At the heart of the anode lies the target metal, the material responsible for generating X-ray photons. Tungsten is the most common target substance because it possesses several desirable properties:

High melting point, enabling it to endure intense thermal loads

High atomic number, making X-ray production more efficient

Good thermal conductivity, helping dissipate heat to surrounding structures

The surface of the target is angled, typically between 6° and 20°, to spread the heat over a wider area and to shape the emerging X-ray beam effectively.

High-Voltage Supply

A crucial part of the tube’s operation is the high-voltage supply, which creates the large potential difference between the cathode and the anode.

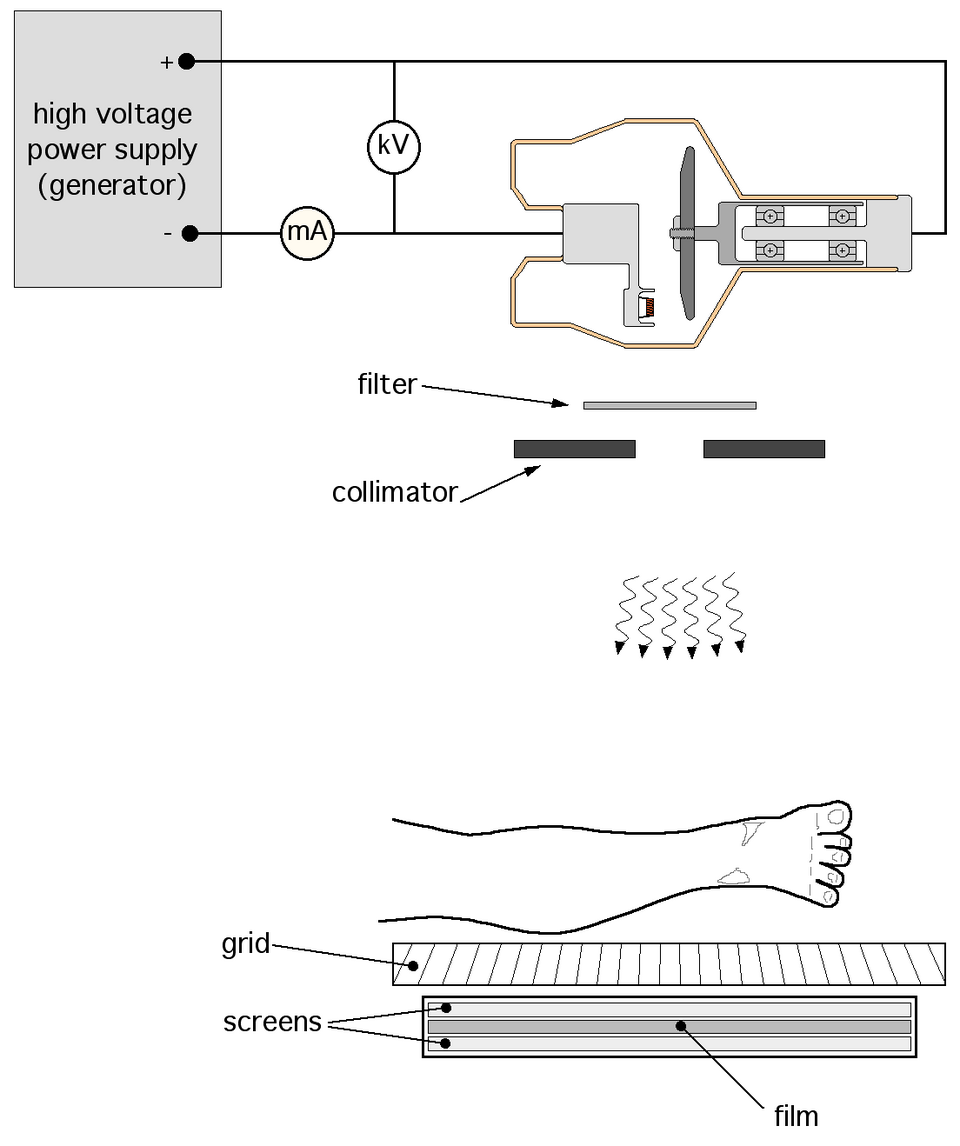

A line-art schematic illustrating the cathode, anode, and high-voltage connections, with surrounding generator components that exceed the OCR requirement but help visualise how the potential difference is supplied to the tube. Source.

EQUATION

—-----------------------------------------------------------------

Electron Kinetic Energy (KE) = eV

KE = Energy gained by an electron (joules)

e = Charge of an electron (coulombs)

V = Accelerating potential difference across the tube (volts)

—-----------------------------------------------------------------

The magnitude of this accelerating voltage typically ranges from 30 kV to 150 kV in medical applications. By adjusting the voltage, operators can control the maximum energy of the emitted X-rays, thus tailoring the beam to the imaging task at hand. Higher voltages produce higher-energy photons capable of penetrating denser tissues.

Between definition and equation blocks, there is sufficient explanatory context to maintain flow, and it is important to understand that while the heater controls the number of electrons emitted, the high-voltage supply determines the energy those electrons possess.

Structural and Support Features

Beyond the core components specified in the syllabus, several support structures ensure safe and reliable operation:

Evacuated tube housing prevents electron collisions with air molecules.

Oil or dielectric fluid around the tube insulates the high voltage and transfers excess heat.

External lead shielding reduces stray radiation.

These additional features ensure that the tube functions consistently, remains electrically safe, and does not overheat during clinical use.

Interactions Within the Tube

When electrons strike the target metal, their sudden deceleration results in photon production through two primary mechanisms:

Bremsstrahlung radiation, arising from the deceleration of electrons in the electric field of atomic nuclei

Characteristic radiation, produced when electrons dislodge inner-shell electrons from the target atoms

Although these mechanisms relate more directly to the production of X-rays, their underlying physics reinforces why the structure of the tube must support extremely high temperatures, strong electric fields, and stable electron trajectories.

Summary of Key Components

To align precisely with the specification requirements, the essential structural elements of an X-ray tube are:

Heater (cathode): Produces electrons through thermionic emission

Anode: Accelerates and absorbs electrons, converting kinetic energy to X-rays

Target metal: Usually tungsten, responsible for X-ray photon production

High-voltage supply: Accelerates electrons and determines photon energy

Each component works in coordination to produce a controlled X-ray beam suitable for diagnostic imaging, and understanding their structure lays the foundation for mastering medical imaging physics.

FAQ

A high vacuum prevents electrons from colliding with air molecules inside the tube. This ensures that electrons travel freely from the cathode to the anode without losing energy.

It also prevents unwanted ionisation and electrical discharge inside the tube, improving stability and reducing the risk of arcing at the very high voltages used.

Maintaining a vacuum also protects the heated filament from oxidising, significantly increasing tube lifespan.

The focal spot is influenced by the design of the focusing cup and the angle of the anode surface.

A smaller focal spot improves image sharpness, as it reduces geometric blurring.

However, smaller spots increase heat concentration, so tubes often use the line-focus principle:

• A steep anode angle creates a large actual focal area for heat dissipation.

• The effective focal spot appears much smaller from the patient’s perspective.

Rotation spreads the heat load over a larger area of the anode surface. This prevents localised overheating, allowing higher tube currents and longer exposure times.

It also extends the operational lifespan of the target metal, as no single point receives continuous electron bombardment.

Rotating anodes therefore enable sharper images and more powerful X-ray output, essential for modern diagnostic imaging.

Heat is managed through several layers of design:

• The rotating anode spreads heat across a wider surface.

• Tungsten’s high thermal conductivity transfers heat deeper into the anode body.

• The anode disc is often backed by molybdenum or graphite to enhance heat dissipation.

• The tube housing contains insulating oil or dielectric fluid to remove heat from the envelope.

Effective cooling prevents damage, warping, and reduced X-ray output.

Ordinary glass absorbs a significant fraction of low-energy X-rays, reducing beam intensity and altering the spectrum.

Tube windows are therefore made from low-attenuation materials such as beryllium. These materials transmit a higher proportion of X-ray photons, ensuring a predictable and efficient output.

The rest of the envelope remains glass or metal because mechanical strength and electrical insulation are prioritised in those regions.

Practice Questions

Question 1 (3 marks)

Describe the roles of the heater (cathode) and the anode in an X-ray tube.

Question 1 (3 marks)

• Heater (cathode) emits electrons by thermionic emission. (1)

• Electrons are directed towards the anode. (1)

• The anode is the positive electrode that rapidly decelerates the electrons to produce X-ray photons. (1)

Question 2 (6 marks)

An X-ray tube contains a heated cathode, a high-voltage supply, and a tungsten anode.

Explain how the tube produces X-ray photons.

In your answer, discuss:

• how electrons are emitted and accelerated

• why a high voltage is required

• the interaction of electrons with the target

• why tungsten is used as the target metal

Question 2 (6 marks)

• Heating the cathode causes thermionic emission of electrons. (1)

• A high potential difference accelerates electrons towards the anode at high speeds. (1)

• Electrons decelerate rapidly when they strike the tungsten target, producing X-rays. (1)

• X-rays are generated mainly through Bremsstrahlung radiation and characteristic radiation. (1)

• Tungsten is chosen because it has a high melting point, allowing it to withstand high temperatures. (1)

• Tungsten has a high atomic number, making X-ray production more efficient. (1)