OCR Specification focus:

‘Describe tensile and compressive deformation; define extension and compression for springs and materials.’

When a material experiences a force, it can change shape by stretching, compressing, or bending. Understanding tensile and compressive deformation—and how extension and compression are defined—is essential for explaining how materials respond to applied forces.

Tension and Compression: The Basis of Deformation

Tensile Deformation

When a tensile force acts on a material, it pulls the material apart, attempting to increase its length. Such deformation is called tensile deformation. The material becomes longer under the action of this stretching force.

Tensile Deformation: The change in shape or length of a material when it is subjected to a pulling or stretching force that increases its length.

A simple example is a metal wire suspended from a support with a weight attached at its free end. The weight exerts a downward force, stretching the wire and increasing its length. If the force is removed, the wire returns to its original length—provided the elastic limit has not been exceeded.

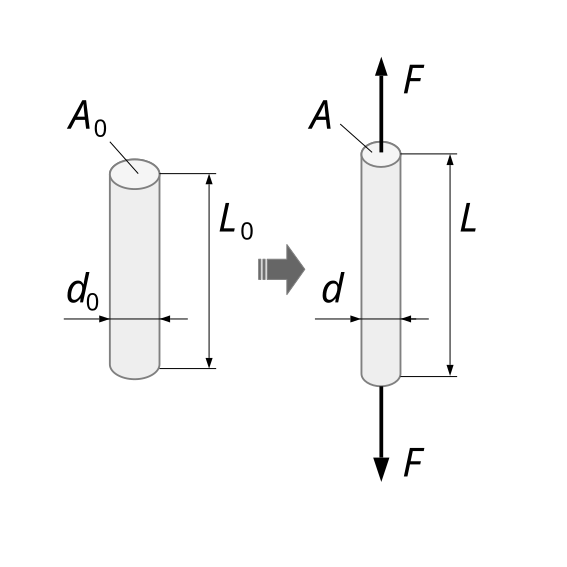

Bar under tension: the applied pulling force increases length along the loading axis. The diagram contrasts the unstressed state with the elongated state under tensile load, reinforcing the concept of tensile deformation. Source.

Compressive Deformation

The opposite of tension is compression. A compressive force pushes or squeezes the material, tending to reduce its length. The deformation that results from compression is known as compressive deformation.

Compressive Deformation: The change in shape or length of a material when a pushing or squeezing force acts to reduce its length.

In practice, compressive deformation can be seen when a spring or foam pad is squashed. If the material is elastic, it will return to its original form after the force is removed.

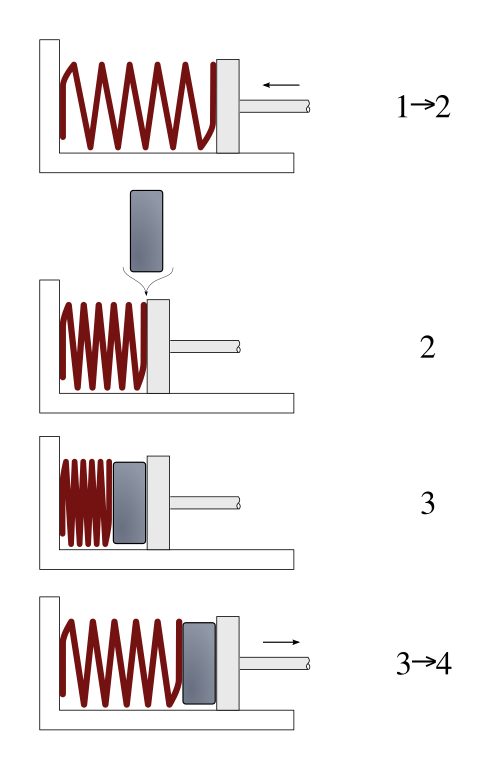

Compression of a coil spring by a piston shortens the spring relative to its natural length. The diagram highlights the direction of applied force and resulting decrease in length, matching the definition of compressive deformation. Source.

Extension and Compression in Springs

Extension

When a spring is stretched, the amount by which its length increases compared to its natural length (its length without any load) is known as the extension.

Extension: The increase in length of a material or spring compared with its original (unstressed) length when subjected to a tensile force.

Extension is a key measurable quantity in many experiments and calculations involving springs. It directly relates to the force applied, according to Hooke’s law, within the elastic region.

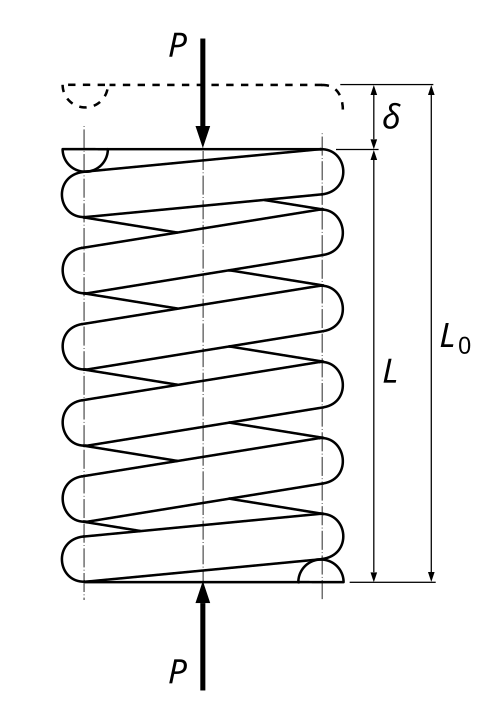

Extension or compression is measured relative to a spring’s natural length L₀. The diagram links applied load P to deflection δ, illustrating measurable change in length under force. (Extra detail: includes a load–deflection curve typical of a compression spring.) Source.

Compression

Similarly, when a spring is compressed, its length becomes shorter than its natural length. The decrease in length compared with the uncompressed state is known as compression.

Compression: The decrease in length of a material or spring compared with its original (unstressed) length when subjected to a compressive force.

The same spring constant (k) that governs extension can also describe compression—provided the spring remains within its elastic limit and behaves linearly.

Understanding Elastic and Inelastic Behaviour

Elastic Deformation

When a material returns to its original shape and size after the applied force is removed, the deformation is elastic. This behaviour arises because the atomic or molecular bonds within the material are stretched or compressed but not permanently displaced.

Elastic Deformation: Temporary deformation in which a material returns to its original dimensions once the applied force is removed.

During elastic deformation, energy is stored within the material as elastic potential energy. This stored energy is recoverable when the material returns to its original shape.

Plastic Deformation

If the applied force is too large, the material may not return to its original dimensions when the force is removed. This is known as plastic deformation—a permanent change in shape due to atomic layers sliding or bonds breaking.

Plastic Deformation: Permanent deformation of a material after the applied stress has exceeded the elastic limit, causing irreversible changes in its structure.

Although the OCR specification for this subsubtopic focuses on tensile and compressive deformation, recognising the distinction between elastic and plastic behaviour helps contextualise when the definitions of extension and compression remain valid.

Forces Acting on Materials: The Atomic Perspective

Microscopic View of Tension and Compression

On a molecular scale:

Tensile forces cause interatomic bonds to stretch, increasing the separation between atoms.

Compressive forces cause atoms to move closer together, reducing the average separation.

In both cases, interatomic forces resist the applied stress. If the deformation remains small, the restoring forces are proportional to the displacement—this is the elastic region of behaviour.

However, beyond a certain point (the elastic limit), atomic bonds may permanently shift or break, leading to plastic or even brittle failure.

Measurement of Extension and Compression

Practical Observations

In laboratory settings, extension and compression can be measured using:

A ruler or vernier scale to record the change in length.

Clamps and stands to ensure consistent support and alignment of the spring or wire.

Slotted masses or weights to apply a controlled force.

The extension (x) is calculated as:

EQUATION

—-----------------------------------------------------------------

Extension (x) = Stretched length – Original length

x = Difference in length (metres, m)

—-----------------------------------------------------------------

This measured extension (or compression) is crucial for constructing force–extension graphs, which are explored in later subsubtopics.

Comparing Tensile and Compressive Effects

Although both tension and compression involve changes in length, their effects on materials differ due to internal structure and bonding:

Metals generally resist tension and compression similarly because of metallic bonding.

Polymers often stretch easily under tension but may buckle under compression.

Brittle materials (like glass or ceramics) resist compression well but fracture under tension.

Understanding these contrasting behaviours is vital for designing structures and choosing materials appropriate for either tensile or compressive loads.

Summary of Key Relationships

To connect the ideas of tension, compression, and deformation clearly:

Tensile forces cause extension (increase in length).

Compressive forces cause compression (decrease in length).

Both are forms of deformation—the change in shape or size due to applied forces.

The degree of deformation depends on the material properties and magnitude of force.

Within the elastic limit, materials return to their original dimensions once the force is removed.

These fundamental definitions form the conceptual basis for later topics such as Hooke’s law, elastic potential energy, and the mechanical properties of matter.

FAQ

The amount of extension or compression depends on:

The magnitude of the applied force — greater force produces greater deformation (within the elastic limit).

The material’s stiffness or force constant (k) — stiffer materials deform less under the same load.

The dimensions of the material — longer or thinner wires extend more easily.

Temperature — increased temperature can slightly reduce stiffness and increase extension.

These factors determine how easily a spring or material changes length under tension or compression.

Some materials, especially polymers and composites, have asymmetric internal structures that respond unevenly to stretching and squeezing.

For example, in foam or rubber, compression causes air pockets or chains to collapse, while tension stretches them. In brittle materials like glass, cracks propagate easily under tension but close under compression.

This asymmetry explains why certain materials resist compression well but fail under tensile stress.

Elastic deformation occurs when interatomic bonds are stretched or compressed but not broken.

Atoms in a solid are arranged in a lattice held by electrostatic forces. When a small force is applied:

Tensile forces slightly increase atomic separation.

Compressive forces decrease it.

If the force is removed before the elastic limit, these forces restore atoms to equilibrium positions, returning the material to its original shape.

Common sources of error include:

Parallax error when reading the scale at an angle.

Zero error if the scale doesn’t start at the true zero position.

Non-uniform spring coils causing uneven extension.

Temperature changes affecting material stiffness.

Misalignment of the load and spring, leading to sideways motion.

Minimising these requires careful alignment, consistent measuring methods, and repeated readings to improve accuracy.

Distinguishing these behaviours helps predict how materials will perform in real applications.

Elastic deformation is reversible, allowing springs or structures to absorb and release energy safely.

Plastic deformation is permanent, which can lead to structural failure or loss of function.

In engineering, knowing where the elastic limit lies ensures that components remain within safe, reversible deformation ranges during use.

Practice Questions

Question 1 (2 marks)

A steel wire is suspended vertically with a small mass attached to its lower end. Explain what is meant by the extension of the wire and state how it can be measured in an experiment.

Mark scheme:

1 mark for stating that extension is the increase in length of the wire compared with its original (unstressed) length.

1 mark for describing that it can be measured by recording the difference between the stretched length and the original length, for example using a ruler or vernier scale.

Question 2 (5 marks)

A student investigates how a helical spring behaves when subjected to both tensile and compressive forces. The student carefully measures the change in length as small weights are added and removed.

(a) Describe the difference between tensile and compressive deformation.

(b) Define extension and compression for the spring in this experiment.

(c) State what happens to the spring when the elastic limit is exceeded.

Mark scheme:

(a)

1 mark for stating that tensile deformation occurs when a material is stretched, increasing its length.

1 mark for stating that compressive deformation occurs when a material is squeezed or shortened under compression.

(b)

1 mark for defining extension as the increase in length of the spring compared with its natural length when stretched.

1 mark for defining compression as the decrease in length of the spring compared with its natural length when compressed.

(c)

1 mark for stating that once the elastic limit is exceeded, the spring does not return to its original shape or length when the force is removed (plastic deformation occurs).