AP Syllabus focus:

‘Innovations such as textile machinery, steam engines, interchangeable parts, the telegraph, and new farm inventions increased production efficiency.’

Industrial Innovation and Expanding Manufacturing Capacity

Industrial advancements during the market revolution fundamentally reshaped production in the United States. New technologies reduced reliance on skilled labor, accelerated output, and concentrated manufacturing in emerging factory centers, especially in the Northeast.

Textile Machinery and the Factory System

The introduction and rapid spread of textile machinery—particularly power looms and spinning machines—helped launch America’s first large-scale industrial sector. Borrowing heavily from British designs, entrepreneurs such as Samuel Slater and Francis Cabot Lowell introduced mechanized production methods that transformed raw cotton into finished cloth with unprecedented speed. These innovations created the factory system, a model in which labor, machines, and production processes were centralized under one roof for maximum efficiency.

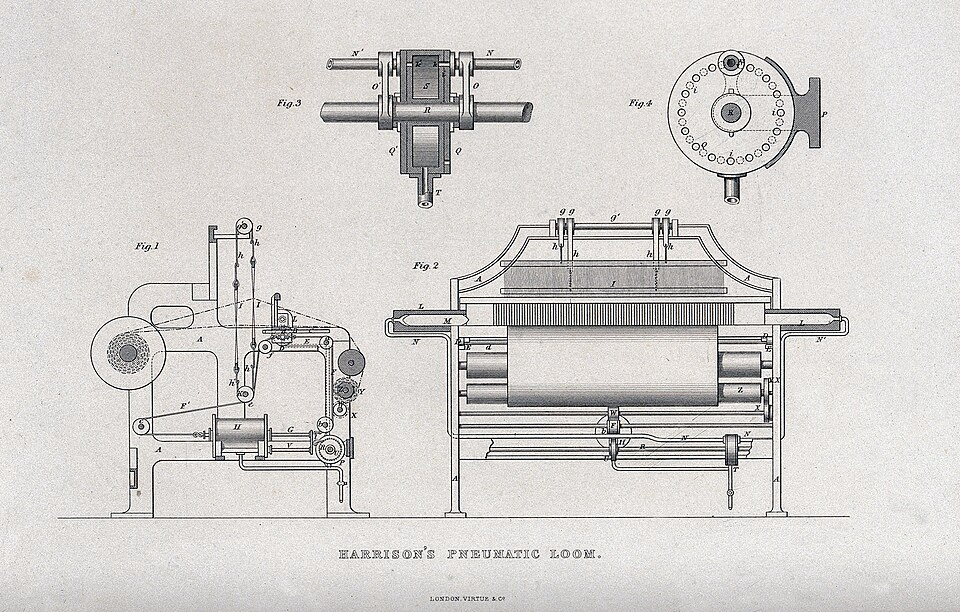

Elevation views of a nineteenth-century power loom highlight the main structural elements of mechanized weaving. The image shows how gears, shafts, and frames coordinated to automate the conversion of thread into cloth. Some labeled mechanical details exceed AP requirements but help visualize how textile machinery increased production efficiency. Source.

Textile mills dramatically increased the volume and consistency of cloth production.

Mechanization reduced dependence on artisanal spinning and weaving.

Mill towns grew around rivers that powered early water-driven machines.

Factory System: A method of production in which workers and machines were gathered in a single location to increase efficiency and output.

As factories multiplied, they stimulated complementary industries, including machine tooling, iron production, and transportation networks necessary to supply and distribute manufactured goods.

The Steam Engine and Mechanized Power

The widespread adoption of the steam engine extended industrialization beyond river-powered sites. Steam provided reliable, portable power, enabling mills, foundries, and workshops to operate in more diverse locations and scale up production.

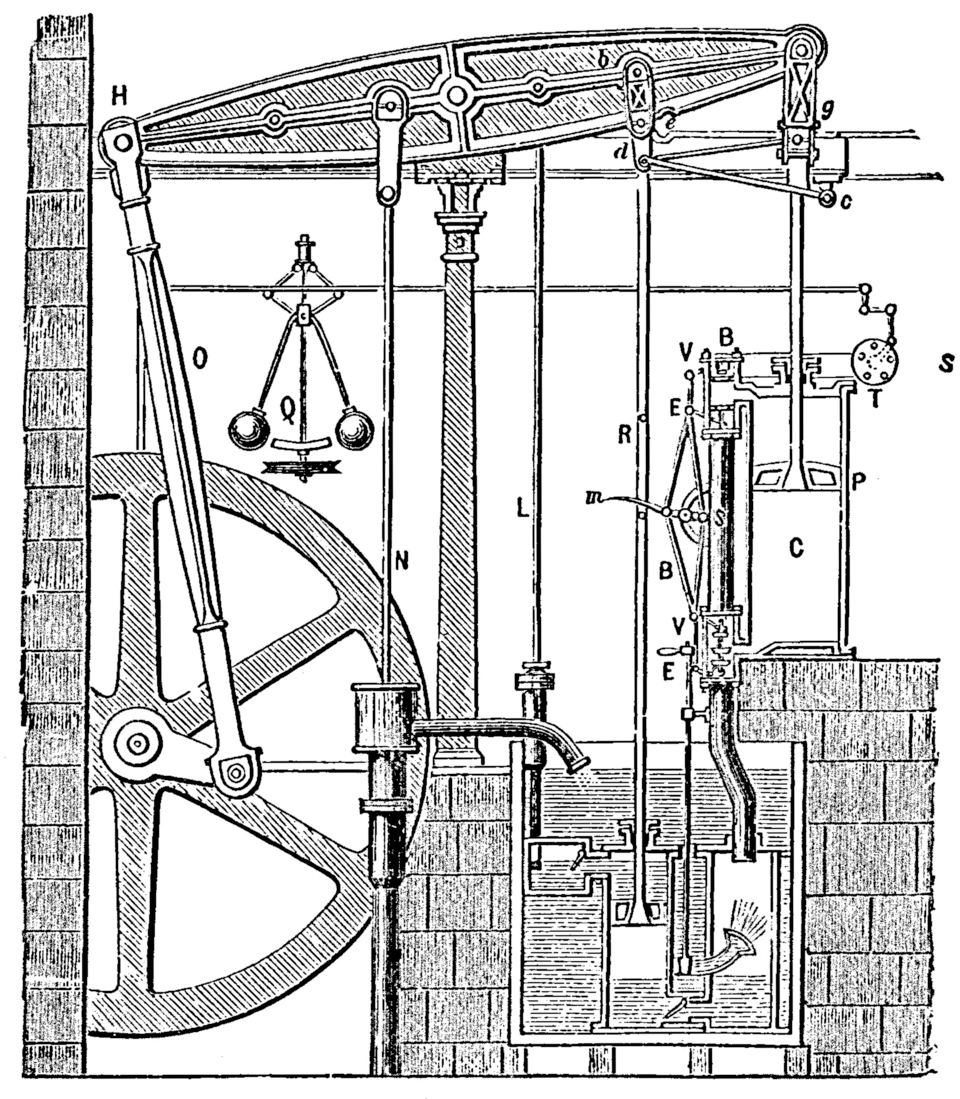

This diagram shows a rotative steam engine designed by Boulton and Watt, with the cylinder, piston, beam, pumps, and governor labeled. It demonstrates how steam pressure was converted into rotary motion used to power industrial machinery. Some highly technical annotations exceed syllabus needs but help illustrate why steam engines expanded factory capabilities. Source.

Factories were no longer restricted to water sources.

Steam-powered machines increased output and operated more continuously.

Steamboats expanded upstream navigation, linking western farmers to national markets.

The growing reliability of steam encouraged investment in urban manufacturing and contributed to the rise of major industrial cities such as Pittsburgh, Cincinnati, and Lowell.

Interchangeable Parts and Standardized Manufacturing

Perhaps the most influential industrial innovation of the era was the development of interchangeable parts, a system attributed largely to Eli Whitney. This method involved producing uniform components that could be easily fitted into any identical product, dramatically streamlining assembly and repair.

Interchangeable Parts: A production system using standardized, identical components that allowed goods to be quickly assembled and easily repaired.

This technique revolutionized manufacturing for firearms, clocks, and later sewing machines, laying essential groundwork for mass production. It reduced reliance on skilled artisans, elevated the role of precision machine tools, and supported the expansion of large workshops capable of producing consistent, high-volume goods.

Communication and Economic Integration

Technological innovation during the period extended beyond machinery to transformative communication systems.

The Telegraph and Rapid Information Flow

Invented by Samuel Morse in the 1830s and adopted widely in the 1840s, the telegraph revolutionized communication by transmitting messages nearly instantaneously across vast distances. Telegraph lines soon connected major cities, business centers, and transportation hubs.

Merchants used telegraph messages to track prices and coordinate shipments.

Railroads adopted telegraph systems for scheduling and safety.

News traveled faster, increasing national awareness and commercial responsiveness.

Telegraph: An electrical communication system that transmitted coded messages over wires, enabling near-instant long-distance information exchange.

The telegraph accelerated economic decision-making and strengthened connections between distant regions participating in the market economy.

Agricultural Innovation and Rising Farm Productivity

While industrialization transformed the Northeast, agricultural innovation reshaped farming across the Midwest and parts of the South. New tools reduced labor demands, boosted yields, and aligned rural production with expanding national and international markets.

Mechanized Farm Tools and Northern Productivity

Northern agriculture benefited from new implements that made cultivation and harvesting more efficient. The most influential inventions included the steel plow, created by John Deere in 1837, and the mechanical reaper, developed by Cyrus McCormick in the 1830s.

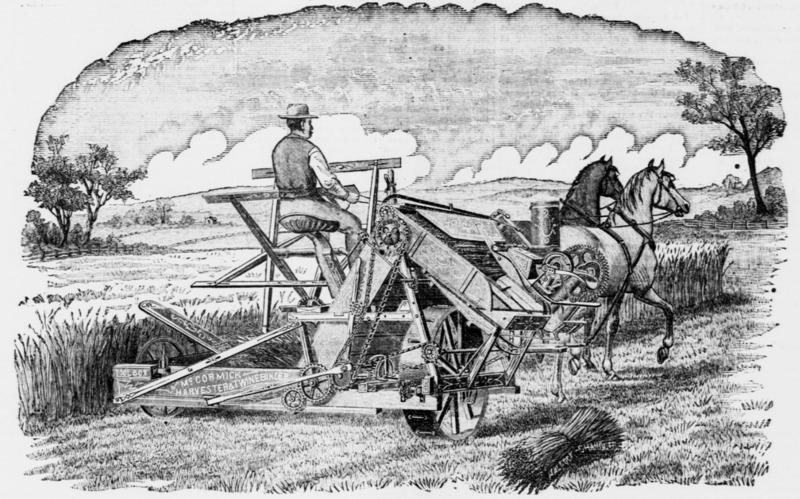

The sketch shows a horse-drawn mechanical reaper harvesting grain while workers guide the machine and manage the cut crop. It illustrates how the reaper combined animal power and technology to harvest far more wheat than hand tools allowed. Field and figure details extend beyond the syllabus but help visualize the tool’s practical operation. Source.

The steel plow cut through tough prairie sod with far less effort, enabling rapid westward expansion of grain farming.

The mechanical reaper allowed farmers to harvest wheat much faster, increasing yields and reducing seasonal labor pressures.

Improved productivity encouraged specialization in cash crops such as wheat and corn.

These tools enabled family farms to manage larger tracts of land and produce surplus crops for distant markets, integrating the Midwest into the national economy.

Cotton Gin and Southern Agricultural Expansion

Although invented slightly earlier (1793), Eli Whitney’s cotton gin remained central to Southern agricultural productivity during this period. By rapidly separating seeds from short-staple cotton, it allowed profitable cultivation across vast areas of the Deep South.

Cotton output surged, fueling the growth of the textile industry.

Planters expanded westward into Alabama, Mississippi, and Louisiana.

The crop became the cornerstone of national and international trade networks.

Agricultural innovation thus intensified regional economic differences: mechanized grain production flourished in the North and Midwest, while cotton agriculture dominated the South.

Productivity, Labor, and Regional Specialization

Together, industrial and agricultural innovations increased national productivity and deepened regional specialization. Industrial centers relied on wage labor, mechanized power, and communication networks, while agricultural regions used new tools to produce larger surpluses for expanding markets. This technological transformation underpinned the broader market revolution, reshaping economic relationships and accelerating the growth of a nationally integrated economy.

FAQ

Factories often divided production into small, repetitive tasks that could be performed quickly with minimal training. This allowed owners to employ large numbers of unskilled or semi-skilled workers at lower wages.

Shift work became increasingly common, ensuring that machinery operated for more hours of the day.

Supervisors and timekeeping systems were introduced to maintain discipline, standardise output, and minimise interruptions in the production process.

The tough prairie sod of the Midwest was extremely difficult to cut using traditional cast-iron ploughs. The steel plough made it practical to cultivate large fields, encouraging rapid agricultural expansion.

As productivity increased, farming families could sustain themselves on bigger plots, which attracted more migrants westward. Towns, markets, and transport links soon developed around these growing farming communities.

Technologies such as steam power created demand for improved transport capable of moving large quantities of goods quickly and reliably.

• Steamboats expanded river trade, connecting rural producers to distant buyers.

• Railways emerged to move manufactured goods and raw materials between regions.

• Better roads and canals followed as states sought to support expanding markets.

These networks reinforced economic integration and encouraged further industrial investment.

Interchangeable parts reduced the need for craftsmen to custom-fit components, diminishing the value of artisanal precision. Many traditional trades experienced declining prestige as machine-based production took precedence.

Some artisans adapted by retraining as machinists or foremen, while others struggled as workshops shifted towards regimented, deskilled labour structures built around uniform components.

Tools such as the mechanical reaper significantly reduced the number of hands needed during harvest time, easing one of the most labour-intensive parts of the farming year.

With less pressure to rely on large family workforces, younger members could pursue schooling or wage labour opportunities.

Households also reorganised daily routines, as mechanisation shortened outdoor tasks and created more structured work patterns throughout the agricultural calendar

Practice Questions

Question 1 (1–3 marks)

Explain one way in which industrial innovation contributed to increased productivity in the United States between 1800 and 1848.

Mark scheme

1 mark for identifying a relevant industrial innovation (for example, steam engines, textile machinery, interchangeable parts).

1 mark for describing how the innovation functioned or what it changed in production.

1 mark for explaining how this specifically increased productivity (for example, faster output, reduced need for skilled labour, greater consistency of manufactured goods).

Question 2 (4–6 marks)

Analyse how agricultural innovations transformed farming practices and contributed to wider economic change in the United States between 1800 and 1848.

Mark scheme

Up to 2 marks for identifying specific innovations (for example, the steel plough, mechanical reaper, cotton gin).

Up to 2 marks for explaining how these innovations altered farming processes (for example, easier soil cultivation, faster harvesting, expanded cotton cultivation).

Up to 2 marks for linking these changes to broader economic effects (for example, increased market-oriented farming, regional specialisation, growth in national and international trade).