OCR Specification focus:

‘Link material resistivity to wire selection in circuits and power distribution.’

Resistivity determines how well materials conduct electricity, influencing wire choice, component design, and energy efficiency. Understanding its applications ensures safe, cost-effective, and sustainable electrical systems.

Resistivity and its Role in Electrical Systems

Resistivity is a fundamental material property defining how strongly a substance opposes current flow. It determines how much energy is lost as heat when charge moves through a material. Engineers and physicists use resistivity to select materials that optimise electrical performance and minimise unwanted power losses.

Resistivity (ρ): The intrinsic property of a material that quantifies how strongly it resists the flow of electric current, measured in ohm metres (Ω m).

Resistivity directly influences a wire’s resistance, which depends on its length and cross-sectional area. This relationship forms the foundation for understanding how to design efficient circuits and transmission systems.

EQUATION

—-----------------------------------------------------------------

Resistance (R) = ρ L / A

ρ = Resistivity of the material (Ω m)

L = Length of conductor (m)

A = Cross-sectional area of conductor (m²)

—-----------------------------------------------------------------

This equation shows that increasing the length of a conductor raises resistance, while increasing its cross-sectional area lowers it. Therefore, the resistivity of the material must be carefully considered alongside geometry to ensure effective circuit performance.

Wire Selection in Circuits

When constructing electrical circuits, choosing the correct wire material and dimensions is vital for safety, reliability, and energy efficiency. The wire’s resistivity determines how much voltage drops along its length and how much heat is generated.

Key Factors in Wire Choice

Material resistivity: Low-resistivity materials, such as copper (1.7 × 10⁻⁸ Ω m), are ideal for most circuit wiring because they conduct efficiently and minimise energy loss.

Mechanical strength: In applications where durability matters, materials like aluminium or constantan may be chosen despite higher resistivity.

Environmental conditions: Corrosive or high-temperature environments demand materials with stable resistivity and suitable chemical resistance.

Cost considerations: Copper offers excellent performance but is more expensive than alternatives; aluminium provides a lighter, cheaper option for large-scale power transmission.

Practical Implications in Circuit Design

In laboratory or domestic circuits, wires must carry current safely without overheating. Higher resistivity causes greater power dissipation as heat, which can damage insulation or components. To prevent this:

Select low-resistivity conductors.

Minimise wire length where possible.

Use thicker wires to reduce resistance.

Even in small circuits, choosing wires with appropriate resistivity ensures accurate potential differences and prevents errors in measurement or device behaviour.

Resistivity and Power Distribution

Resistivity plays a pivotal role in power generation and transmission. Electrical energy must travel long distances from power stations to consumers, and any resistivity in the transmission lines causes energy losses due to heating.

EQUATION

—-----------------------------------------------------------------

Power Loss (Pₗ) = I²R

I = Current through the conductor (A)

R = Resistance of the conductor (Ω)

—-----------------------------------------------------------------

Power losses increase dramatically with current, so engineers reduce these losses by designing transmission systems to operate at high voltages and low currents, thereby minimising I²R heating.

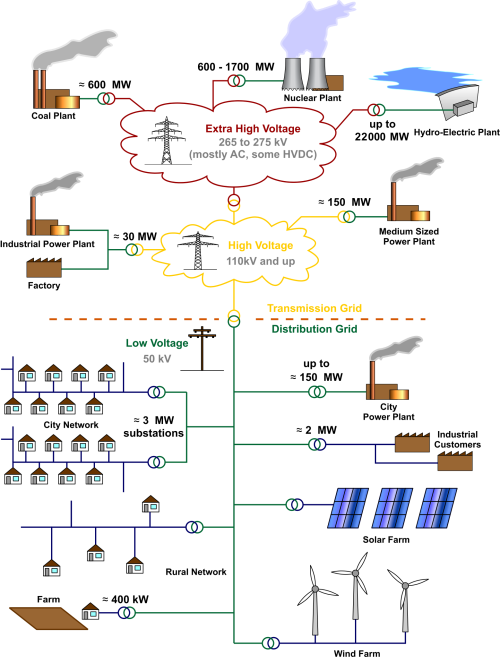

Schematic of an electric power system showing step-up transformers at generation, high-voltage transmission lines, and step-down transformers for distribution. It clarifies why grids raise voltage to limit I²R losses in long lines. The diagram also includes ancillary elements (e.g. generation types) beyond the syllabus focus. Source.

Since resistance depends on both the conductor’s resistivity and its geometry, materials with very low resistivity, such as copper or aluminium, are essential.

Applications in National Grids

In high-voltage transmission:

Aluminium is widely used for overhead cables due to its low density, moderate resistivity, and cost-effectiveness.

Steel cores are often added to aluminium cables (forming ACSR – Aluminium Conductor Steel Reinforced) to enhance tensile strength without significantly increasing resistivity.

Cross-section of an ACSR transmission cable showing multiple aluminium strands surrounding a central steel core. Aluminium provides low resistivity and good conductivity; the steel core supplies mechanical strength for long spans. The red band is mounting tape and not part of the conductor. Source.

In underground or submarine cables, copper may be used where compactness and superior conductivity outweigh cost considerations.

These applications demonstrate how understanding resistivity ensures efficient energy delivery and reduces waste in national and regional power networks.

Resistivity in Specialist Applications

Beyond power lines, resistivity underpins material selection for a wide range of electrical and electronic technologies.

Heating Elements

In devices such as electric kettles or toasters, materials with high resistivity are desirable. Nichrome (an alloy of nickel and chromium) offers both high resistivity and excellent temperature stability, converting electrical energy into heat efficiently and safely.

Precision Components

Some instruments require stable resistivity over a range of temperatures to ensure consistent performance. Manganin and constantan are used in precision resistors and strain gauges because their resistivity changes very little with temperature.

Superconductors

At the opposite extreme, certain materials become superconductors at very low temperatures, meaning their resistivity drops to zero. This allows current to flow indefinitely without energy loss. Applications include:

Magnetic resonance imaging (MRI) machines

Particle accelerators

Magnetic levitation systems

While not yet practical for everyday circuits, superconductivity represents the ultimate exploitation of resistivity control.

Safety, Efficiency, and Sustainability

Resistivity also affects thermal management and energy efficiency. Excess resistivity in wiring or connectors increases heat generation, risking component damage and fire hazards. Therefore:

Cables must be chosen with suitable current ratings.

Conductors should have insulation capable of withstanding expected temperatures.

Systems must include protection (e.g. fuses or circuit breakers) to prevent overheating due to excessive resistance.

Reducing resistive losses is not only about performance but also environmental impact. Lower resistivity in transmission lines means less wasted energy and smaller carbon footprints for electricity networks. Modern innovations aim to:

Develop materials with improved conductivity.

Use high-temperature superconductors for future low-loss transmission.

Optimise circuit designs to minimise unnecessary resistive paths.

Summary of Core Applications

Circuit wiring: Low-resistivity materials ensure efficient current flow and stable potential differences.

Power transmission: Minimising resistivity reduces energy losses and improves grid efficiency.

Heating devices: High-resistivity materials enable controlled heat generation.

Measurement systems: Stable resistivity ensures reliable sensor and resistor performance.

Advanced technologies: Superconducting materials eliminate resistive losses altogether.

Understanding and applying the principles of resistivity enable engineers and physicists to design circuits that are efficient, safe, and environmentally responsible — precisely aligning with the OCR specification’s emphasis on linking material resistivity to wire selection and power distribution.

FAQ

Voltage drop occurs because energy is lost as charge moves through a resistive conductor. The greater the resistivity, the more voltage is lost per unit length.

To minimise voltage drop:

Use conductors with low resistivity, such as copper or aluminium.

Increase the cross-sectional area of the wire to lower resistance.

Keep cable runs as short as possible.

This is especially important in precision instruments and distribution networks, where voltage consistency is critical.

Copper has lower resistivity than aluminium, which allows for smaller cable diameters while maintaining the same current capacity.

Underground cables must also dissipate heat effectively; copper’s better conductivity reduces heat build-up.

Additionally, copper’s strength and flexibility simplify installation and improve reliability under thermal expansion and ground movement conditions.

The higher cost is justified where space is limited or where repair access is difficult.

Using a material with high resistivity would lead to excessive energy loss through heating, described by P = I²R.

Consequences include:

Increased thermal expansion and risk of cable failure.

Reduced efficiency and higher operational costs.

Greater environmental impact due to wasted energy.

This is why transmission lines use low-resistivity metals and operate at high voltage to keep current — and therefore losses — low.

As temperature rises, the resistivity of metallic conductors typically increases. This is due to greater lattice vibrations that impede electron flow.

Practical implications:

Higher resistance increases power losses and heating.

Cable current ratings must allow for thermal effects under heavy load.

Some systems use monitoring sensors to detect temperature increases and adjust load accordingly.

In extreme conditions, this can limit transmission efficiency or cause safety shut-downs.

Besides resistivity, engineers must consider:

Density: Lower mass reduces mechanical load on structures.

Tensile strength: Ensures cables resist stretching and sagging.

Corrosion resistance: Maintains long-term reliability, especially outdoors.

Thermal conductivity: Helps dissipate heat generated by current flow.

Cost and availability: Affect economic viability for large networks.

Balancing these factors ensures efficient, durable, and safe power distribution systems.

Practice Questions

Question 1 (2 marks)

Explain why aluminium is often chosen instead of copper for overhead power transmission lines, even though aluminium has a higher resistivity.

Mark Scheme:

1 mark: Aluminium is less dense/lighter than copper, reducing mechanical load on pylons.

1 mark: Aluminium is cheaper and still has acceptably low resistivity for efficient transmission.

Question 2 (5 marks)

An engineer is designing cables for a long-distance power transmission system.

(a) Explain why the cables are designed to carry electricity at a high voltage and a low current. (3 marks)

(b) Suggest why the aluminium conductors used are reinforced with steel cores. (2 marks)

Mark Scheme:

(a)

1 mark: Power losses in transmission lines are due to heating, given by P = I²R.

1 mark: Reducing current reduces power loss for the same power output.

1 mark: Operating at high voltage allows lower current for the same transmitted power, improving efficiency.

(b)

1 mark: Steel cores provide tensile strength and support for the aluminium strands.

1 mark: This prevents sagging and breakage over long spans, without significantly increasing total resistivity.