OCR Specification focus:

‘Use Quickfit apparatus for distillation and heating under reflux safely and effectively during organic preparations and purifications.’

Quickfit apparatus enables safe, controlled heating and purification during organic synthesis. Mastering reflux and distillation techniques is essential for producing pure products and preventing loss of volatile organic compounds.

Quickfit Apparatus: Purpose and Core Principles

Quickfit glassware is specially designed, standardised laboratory apparatus that forms gas-tight, heat-resistant assemblies for organic reactions. Components share standard ground-glass joints, allowing secure, leak-free connections when assembling reflux or distillation systems. Students must understand how each piece supports controlled heating, separation and purification in accordance with the OCR specification.

Key Terminology in Quickfit Assemblies

Ground-glass joints, found on most Quickfit components, allow tight connections without clamps on every joint. Joints are matched by size (e.g., 24/29), and light application of grease may be used when necessary (except on joints exposed to aqueous solutions, where grease can contaminate products).

Reflux: A heating technique in which vapours condense and return to the reaction mixture, enabling continuous heating without loss of volatile reactants.

Reflux allows reactions requiring prolonged heating to proceed safely, reducing the risk of flammable vapours escaping.

Heating Under Reflux

Reflux is widely used in organic synthesis when reactions proceed slowly at elevated temperature. Its core function is to maintain a reaction mixture at its boiling temperature while preventing loss of volatile species.

Essential Reflux Components

A standard reflux setup includes the following Quickfit items:

Round-bottom flask (reaction vessel)

Vertical condenser, usually a Liebig or Allihn condenser

Heat source, commonly a water bath, oil bath or heating mantle

Stand and clamps to secure the apparatus

Anti-bumping granules to ensure smooth boiling

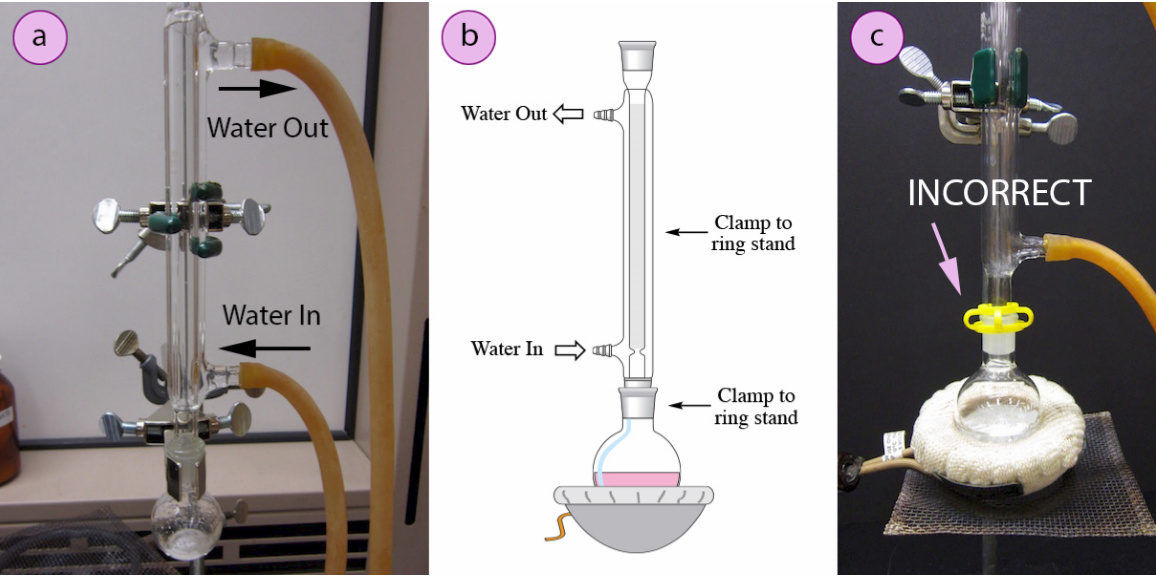

Setting Up a Reflux System

To assemble a typical reflux system safely:

Attach the condenser vertically to the flask using a correctly matched ground-glass joint.

Secure the apparatus using clamps so the joint is not under strain.

Fit water hoses with cold water entering at the bottom and exiting at the top to ensure efficient cooling.

Place the flask in the selected heating bath, ensuring even heat distribution.

Add anti-bumping granules before heating to prevent sudden boiling surges.

The reflux condenser returns condensed vapours to the flask, enabling continuous reaction without solvent loss, which is important when heating flammable liquids.

Reflux apparatus with a vertical condenser demonstrating correct water-flow direction and proper clamping; additional illustrations show incorrect clamping, which can be disregarded for OCR purposes. Source

Safety Considerations in Reflux

Good laboratory practice is essential:

Do not seal the top of the condenser; the system must remain open to the atmosphere to avoid dangerous pressure buildup.

Use appropriate personal protective equipment (gloves, goggles, lab coat).

Check all joints for secure seating and correct alignment before heating.

Ensure water hoses are firmly attached to avoid flooding or overheating if coolant flow stops.

Distillation Using Quickfit Apparatus

Distillation separates components of a mixture based on different boiling points. In organic synthesis, it is used to purify liquids, remove solvents, or isolate products as required by the specification.

Definitions and Core Concepts

Distillation: A purification technique involving vaporisation of a liquid followed by condensation to separate components with different boiling points.

Distillation builds on the apparatus used for reflux but includes components that direct vapours towards collection rather than back into the reaction vessel.

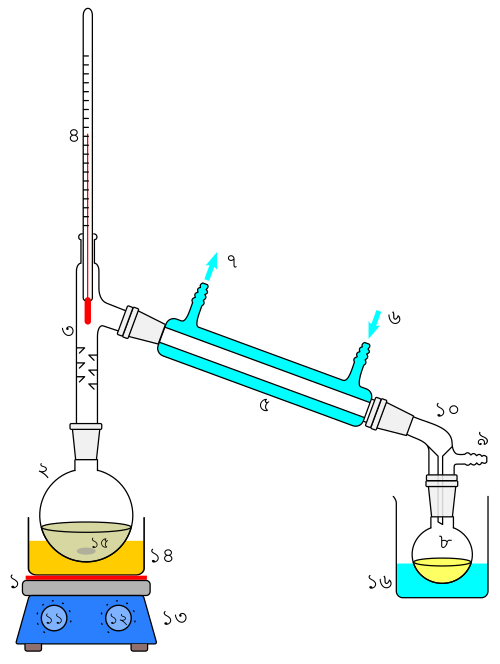

Simple distillation apparatus showing Quickfit components, condenser water-flow direction, and collection setup; extra labelled features extend beyond OCR requirements and may be disregarded. Source

Essential Quickfit Components for Distillation

A typical distillation setup includes:

Round-bottom or pear-shaped flask containing the mixture

Still head to channel vapour flow

Thermometer adapter and thermometer for monitoring vapour temperature

Condenser positioned diagonally

Receiver adapter to direct distillate into the collection vessel

Collection flask

Heating mantle or bath

Assembling a Distillation Apparatus

To construct the distillation system effectively:

Fit the still head to the reaction flask using ground-glass joints.

Insert a thermometer through the adapter so the bulb sits at the point where vapour enters the condenser, ensuring accurate measurement of vapour temperature.

Attach the condenser to the still head at a downward angle to allow distillate to flow easily.

Connect the condenser outlet to a receiver adapter and then to the collection flask.

Ensure coolant flows from bottom to top through the condenser.

Heat the mixture gradually to avoid sudden boiling and formation of impurities.

Fractional vs Simple Distillation

While the specification does not require detailed mechanism, familiarity with the difference is helpful:

Simple distillation is used when boiling point differences are large.

Fractional distillation uses a fractionating column to separate liquids with closer boiling points.

Students should recognise how apparatus choice affects purity and efficiency during purification.

Safety Considerations in Distillation

Important guidance includes:

Never distil to dryness, as organic residues may overheat and decompose.

Secure all components to avoid misalignment as heating progresses.

Avoid applying grease to joints that must remain clean for accurate temperature readings.

Do not block the system; pressure buildup can cause explosive failure.

Practical Effectiveness in Organic Preparations

Correct assembly and operation of Quickfit reflux and distillation apparatus allow students to:

Carry out organic syntheses requiring sustained heating.

Minimise loss of volatile materials.

Purify liquid organic products efficiently.

Maintain high safety standards during practical work.

These skills directly reflect the OCR specification focus on using Quickfit apparatus effectively for distillation and heating under reflux in organic preparations and purifications.

FAQ

Several condenser types are compatible with Quickfit assemblies. The most common are Liebig, Allihn and Graham condensers.

A Liebig condenser provides straightforward cooling for most reflux and simple distillation setups.

An Allihn condenser, with its multiple bulbs, increases surface area and is preferred when more efficient condensation is required.

A Graham condenser contains a coiled tube, offering very high cooling efficiency but is more fragile and often unnecessary for routine A-Level work.

Anti-bumping granules promote smooth, even boiling by creating nucleation sites for bubble formation. Without them, the mixture may boil violently.

They must be added before heating begins. Adding them to a hot mixture can trigger sudden, hazardous boiling.

Magnetic stirring can be used as an alternative in more advanced laboratory settings.

The choice depends on solvent boiling point, flammability and the required level of temperature control.

Water baths suit low-boiling, flammable solvents.

Oil baths offer higher temperature stability for solvents above 100 °C.

Heating mantles are used for very high temperatures and for maintaining even heating around round-bottom flasks.

Avoid naked flames when working with flammable organic liquids.

Before starting the reaction, ensure:

All joints are clean, dry and correctly seated.

Clamps support the apparatus without stressing the glass.

Water hoses are firmly attached and positioned to avoid accidental detachment.

The thermometer adapter is secure if used.

A brief “cold run” with water flowing through the condenser helps confirm stability and proper coolant direction.

Reflux is chosen when the aim is to complete a reaction rather than separate products. It ensures full conversion by preventing loss of volatile reactants.

Distillation is preferred when isolating a product formed at a distinct boiling point or when removing a solvent or by-product.

In multi-step syntheses, reflux may precede distillation to ensure the mixture is fully reacted before purification begins.

Practice Questions

A student sets up a reflux apparatus to heat an organic reaction mixture.

(a) State why reflux heating is used in organic synthesis.

(b) Explain why the condenser must be left open to the atmosphere.

(2 marks)

(a)

Reflux allows the reaction mixture to be heated for an extended period without loss of volatile reactants or solvent. (1)

(b)

The condenser must be open to prevent pressure buildup. (1)

(Allow: prevents apparatus explosion / allows gases to escape safely.)

A student assembles the following distillation apparatus to purify an impure liquid product: a round-bottom flask, still head, thermometer, condenser, receiver adapter and collection flask.

(a) Describe how the thermometer should be positioned and explain why this is important.

(b) State the correct direction of water flow through the condenser and explain why this direction is required.

(c) Give two safety considerations the student must follow when carrying out a distillation.

(5 marks)

(a)

The thermometer bulb should be positioned at the opening to the condenser / at the point where vapour enters the condenser. (1)

Ensures accurate measurement of the vapour temperature / boiling point of the distillate. (1)

(b)

Cold water enters at the bottom of the condenser and leaves at the top. (1)

This ensures the condenser fills completely with water and maintains efficient cooling. (1)

(Allow: maintains a temperature gradient for effective condensation.)

(c)

Any two of the following:

Never distil to dryness. (1)

Ensure all glassware is clamped securely. (1)

Do not block the apparatus; it must remain open to prevent pressure buildup. (1)

Check all water connections are secure to prevent leaks or hose detachment. (1)